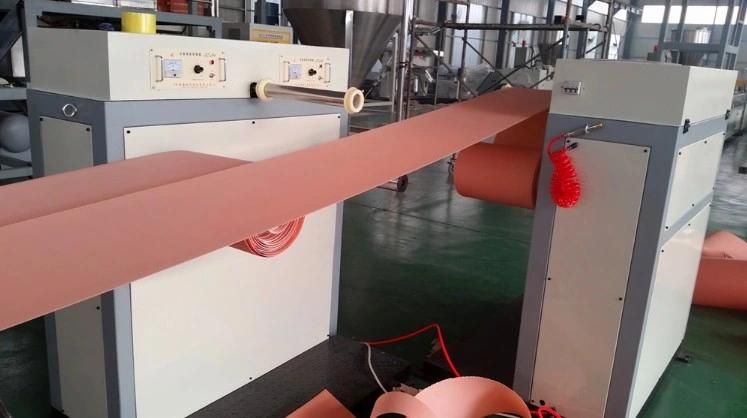

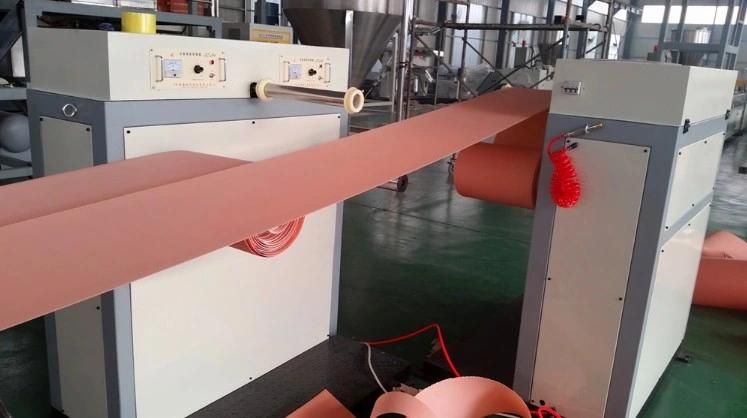

China PVC Sheet Edge Banding Making Extruding Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- Product Type:PVC Sheet

- Board Layers:Multilayer

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJSZ 65,132

- Customized:Customized

- Condition:New

- L/D Screw:22:1

- Power Screw:37 Kw

- out Put:200-250 Kgt,H

- Material:PVC Powder

- Diamter Screw:65 132mm

- Warranty:1 Year

- Weight:10 T

- Width:400 500 600 700 800 1000

- Thickness:0.2-20mm

- Transport Package:Packing Inwooden Case

- Specification:23*2*3m

- Trademark:Tongsan

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:200-250 Kg,H

Description

one set

Detailed Images

1. SJSZ65/132 connical double screw extruderscrew material feeding device Siemens motor ABB inverter OMRON temperature controllerSiemens low voltage appliance

2. mold Reasonable structure of mould should be chosen in terms of material, whereas moulds of clothes-rack mode are widely accepted to regulate flow-distribution and guarantee even thickness of plates (sheets).mold material: hot work steel, 5CrNiMo,mold chamber and mirror surface under polish treatment

3. Three roller calendaring machine for Plastic sheet extrusion machineInclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets).roller surface is under intermediate frequency quenching treatment, hardness HRC>55 degreeunder hard chrome plating treatment, harness is HRC62 degree, surface roughness is Ra0.25Umfour road wheels that can adjust the height separately and is easy to adjust the hrizontal positionthree helica gear hard surface reduction box tht can drive separately or linkage. three roler machine can be synchronization regulated with tractor

3. Three roller calendaring machine for Plastic sheet extrusion machineInclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets).roller surface is under intermediate frequency quenching treatment, hardness HRC>55 degreeunder hard chrome plating treatment, harness is HRC62 degree, surface roughness is Ra0.25Umfour road wheels that can adjust the height separately and is easy to adjust the hrizontal positionthree helica gear hard surface reduction box tht can drive separately or linkage. three roler machine can be synchronization regulated with tractor

4. Temperature controllerheating and cooling medium: oil temperature control range: 30-150three roller temperature controls can be adjusted separately

4. Temperature controllerheating and cooling medium: oil temperature control range: 30-150three roller temperature controls can be adjusted separately

5. Cooling bracketlength 5000mm roller material: 304 stainless steel under polish treatment

5. Cooling bracketlength 5000mm roller material: 304 stainless steel under polish treatment

6. edge cutting devicvethe edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge.Cutting by: high quality alloy knives.

6. edge cutting devicvethe edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge.Cutting by: high quality alloy knives.

Quantity of Knives: two sets

7. edge wastage coiling deviceit will be crushed and milled, then mix with new material for reuse

8. midddle cutting device.middle cutting used to cut wide sheet into narrow sheet

9. haul off machineDouble roller haul off machine

9. haul off machineDouble roller haul off machine

Roller material: rubber

roller up and down: by cylinder control

Speed control: Frequency

10. Cutting machineIt is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance.

10. Cutting machineIt is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance.

11. coiling device double working position equip meter counting and alarming device pad shaft expansion

11. coiling device double working position equip meter counting and alarming device pad shaft expansion

Our services

2.Provide the standard device and the flow chart

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the machine

4.Welcome to visit our factory or the domestic clients' factory.

Services during the sales

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Inspect the machine before leaving the factory.

3.Send our experienced workers and engineer to your factory for installing and adjusting all the machine

4.Train the first-line operator.

5.Provide the basic formula

After sale services

1.One year warranty

2.24 hours online service

3.Engineers available to service machinery overseas

4.Provide technical exchanging

Detailed Images

1. SJSZ65/132 connical double screw extruderscrew material feeding device Siemens motor ABB inverter OMRON temperature controllerSiemens low voltage appliance

2. mold Reasonable structure of mould should be chosen in terms of material, whereas moulds of clothes-rack mode are widely accepted to regulate flow-distribution and guarantee even thickness of plates (sheets).mold material: hot work steel, 5CrNiMo,mold chamber and mirror surface under polish treatment

3. Three roller calendaring machine for Plastic sheet extrusion machineInclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets).roller surface is under intermediate frequency quenching treatment, hardness HRC>55 degreeunder hard chrome plating treatment, harness is HRC62 degree, surface roughness is Ra0.25Umfour road wheels that can adjust the height separately and is easy to adjust the hrizontal positionthree helica gear hard surface reduction box tht can drive separately or linkage. three roler machine can be synchronization regulated with tractor

3. Three roller calendaring machine for Plastic sheet extrusion machineInclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets).roller surface is under intermediate frequency quenching treatment, hardness HRC>55 degreeunder hard chrome plating treatment, harness is HRC62 degree, surface roughness is Ra0.25Umfour road wheels that can adjust the height separately and is easy to adjust the hrizontal positionthree helica gear hard surface reduction box tht can drive separately or linkage. three roler machine can be synchronization regulated with tractor 4. Temperature controllerheating and cooling medium: oil temperature control range: 30-150three roller temperature controls can be adjusted separately

4. Temperature controllerheating and cooling medium: oil temperature control range: 30-150three roller temperature controls can be adjusted separately 5. Cooling bracketlength 5000mm roller material: 304 stainless steel under polish treatment

5. Cooling bracketlength 5000mm roller material: 304 stainless steel under polish treatment 6. edge cutting devicvethe edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge.Cutting by: high quality alloy knives.

6. edge cutting devicvethe edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge.Cutting by: high quality alloy knives.Quantity of Knives: two sets

7. edge wastage coiling deviceit will be crushed and milled, then mix with new material for reuse

8. midddle cutting device.middle cutting used to cut wide sheet into narrow sheet

9. haul off machineDouble roller haul off machine

9. haul off machineDouble roller haul off machineRoller material: rubber

roller up and down: by cylinder control

Speed control: Frequency

10. Cutting machineIt is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance.

10. Cutting machineIt is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance. 11. coiling device double working position equip meter counting and alarming device pad shaft expansion

11. coiling device double working position equip meter counting and alarming device pad shaft expansion Our services

Pre-sale services

1.Provide the free consultation of the machine2.Provide the standard device and the flow chart

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the machine

4.Welcome to visit our factory or the domestic clients' factory.

Services during the sales

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Inspect the machine before leaving the factory.

3.Send our experienced workers and engineer to your factory for installing and adjusting all the machine

4.Train the first-line operator.

5.Provide the basic formula

After sale services

1.One year warranty

2.24 hours online service

3.Engineers available to service machinery overseas

4.Provide technical exchanging