PP Cup/PP Battery Box Waste Plastic Recycling Machine

Jiangsu Mooge Machine Co., Ltd.- Material Processed:Plastic Bottle

- Plastic Type:PE

- Screw:Single-Screw

- Automation:Automation

- Computerized:Non-Computerized

- Certification:ISO9001:2008, CE

Base Info

- Model NO.:ME

- Color:Deaigned

- Capacity:200-1000kg,hr

- Final flake size:12-14mm

- Voltage:customized

- Transport Package:Standard Export Packaging

- Specification:According to the different model

- Trademark:MOOGE

- Origin:Jiangsu, China

- HS Code:84778000

- Production Capacity:3 Set,Sets Per Month

Description

Overview

Product Description

Product ParametersFeatures At A Glance

Conveyor Belt Semi-Metal Detector Machine

Function: used to feeding the bottles into crusher machine Once there is metal passing it, it will alarm and stop the sorting conveyor, after pick out the metal then start it again

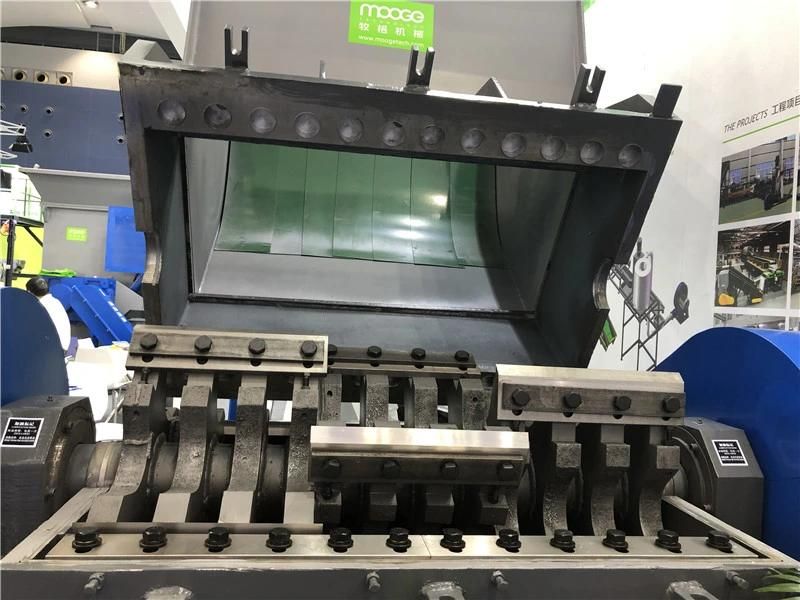

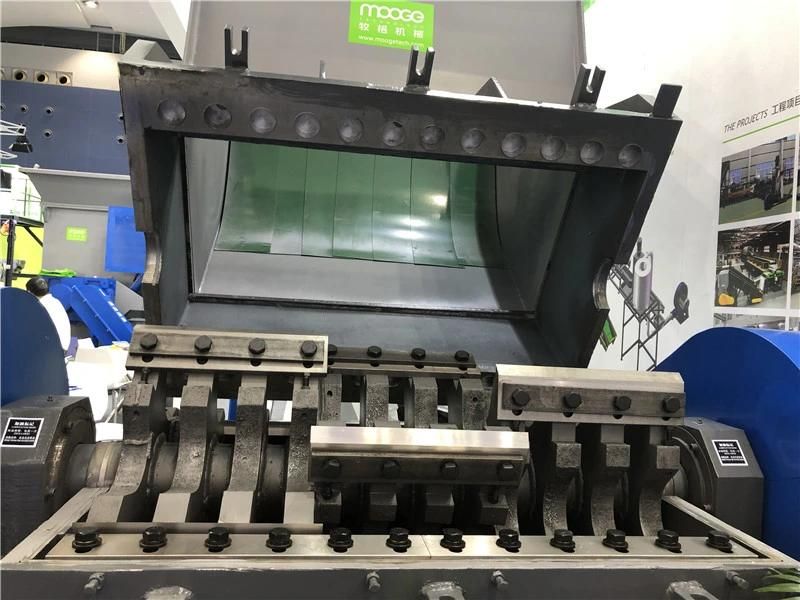

Crusher Machine

Crusher Machine

crushing the material into flakes With water inlet do wet crushing

This series blades are more wider, it will save the blades cost Use the big roller bearing ensure its long time

Bearing house is outside of the crusher chamber so no dirty goes inside for longer use

Machine up chamber is higher and covered by belt no flakes pop out

Friction Wahser Loader Machine

Function: Friction washing the material and loading up it

Up and down both mounted with bearing design

With water injection system to cleaning the screen

Bottom with water drain system

Washing off the dirty and loading the material out to next step processing

Floating Washing Tank

Function: Washing the flakes, prevent dirty going into next process

The roller is specially made can have more

washing for lakes but less water take out

Bottom with Positive and negative screw to pushingthe dirty into middle

Horizontal Dewatering Machine Hot air dryer system Function: take out dirty and remover water Function: Drying the material With the roller bearing and fixed outside of rotor for long use life

Inside with mesh layer, mesh diameter: 3mm

With water spray system to clean the mesh

Packaging & Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

Our Services

1.Pre-sale: we given client the details technician offer, sign the sales contract etc

2.In-sales: we supply the details layout, installation instruction, technician support for the clients

3.After sales: we arrange engineer to install the machinery and training the workers for client

4.We have 24hours team to solve the after sales problem

5.We have free spare parts with the machine

6.We supply long term spare parts for every customer

7.We always update the new technology to every customer

FAQ

1.How to Choose proper Products you want?

Please tell us as detail as what you want

What's your raw material it is

What's the final products you want to produce

What capacity you want it performance

2.How to Control the quality?

We have technical, engineer team design the sample machinery before enter into market

Production QC team ensure the machine manufacturing quality

We will running every machine after finished before shipment

Product Parameters

Conveyor Belt Semi-Metal Detector Machine

Function: used to feeding the bottles into crusher machine Once there is metal passing it, it will alarm and stop the sorting conveyor, after pick out the metal then start it again

Crusher Machine

Crusher Machine crushing the material into flakes With water inlet do wet crushing

This series blades are more wider, it will save the blades cost Use the big roller bearing ensure its long time

Bearing house is outside of the crusher chamber so no dirty goes inside for longer use

Machine up chamber is higher and covered by belt no flakes pop out

Friction Wahser Loader Machine

Function: Friction washing the material and loading up it

Up and down both mounted with bearing design

With water injection system to cleaning the screen

Bottom with water drain system

Washing off the dirty and loading the material out to next step processing

Floating Washing Tank

Function: Washing the flakes, prevent dirty going into next process

The roller is specially made can have more

washing for lakes but less water take out

Bottom with Positive and negative screw to pushingthe dirty into middle

Horizontal Dewatering Machine Hot air dryer system Function: take out dirty and remover water Function: Drying the material With the roller bearing and fixed outside of rotor for long use life

Inside with mesh layer, mesh diameter: 3mm

With water spray system to clean the mesh

Packaging & Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

Our Services

1.Pre-sale: we given client the details technician offer, sign the sales contract etc

2.In-sales: we supply the details layout, installation instruction, technician support for the clients

3.After sales: we arrange engineer to install the machinery and training the workers for client

4.We have 24hours team to solve the after sales problem

5.We have free spare parts with the machine

6.We supply long term spare parts for every customer

7.We always update the new technology to every customer

FAQ

1.How to Choose proper Products you want?

Please tell us as detail as what you want

What's your raw material it is

What's the final products you want to produce

What capacity you want it performance

2.How to Control the quality?

We have technical, engineer team design the sample machinery before enter into market

Production QC team ensure the machine manufacturing quality

We will running every machine after finished before shipment