HDPE Two Layer Plastic Jacket Shell Co-Extruder for Pre-Insulation Pipe Line

Qingdao Huashida Machinery Co., Ltd.- After-sales Service:All Life

- Warranty:6-12monthes

- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:HDPE Jacket Pipe

- Feeding Mode:One Feed

Base Info

- Model NO.:110-600mm

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Total Power:160kw

- Plasticizing Output:250-300kg,H

- Material:PE, PP Raw Material

- Processing Line Length:36000mm

- Transport Package:Wooden and Plastic Film

- Specification:dia. 110-600MM

- Trademark:Huashida

- Origin:Qingdao China

- HS Code:84772090

- Production Capacity:100 Units,Year

Description

Basic Info.

Model NO. 110-600mm Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Total Power 160kw Plasticizing Output 250-300kg/H Material PE, PP Raw Material Processing Line Length 36000mm Transport Package Wooden and Plastic Film Specification dia. 110-600MM Trademark Huashida Origin Qingdao China HS Code 84772090 Production Capacity 100 Units/YearProduct Description

HDPE two layer plastic jacket shell co-extruder for pre-insulation pipe line

Technology: Vacuum Calibrating Method

Advantage:

Vacuum calibrating method pre-insulated pipe outside casing extrusion line is the most advanced and popular machinery in the world. HSD brand absorbs the advanced technology from German and improve to meet development. Especially compared with internal pressure method, Vacuum calibrating method is much better than it for stiffness, pressure resistance and surface smooth.

We aopt PLC automatic operation , Big length-radius proportion screw stem to improve extrusion capacity, optimized design for extrusion mould, Planet cutter suitable for varioul size pipe, and so on. So You choose HSD machinery then you choose saving cost and steady capability and lifelong service etc.

Pipe Application:

PE Pipe produced by this line, is with excellent stiffness, flexibility, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage and so on.

It has become the first choice for the city gas pipe, water supply pipe, foundation pipe, landfill collection pipe, watermain, geothermal heating etc.

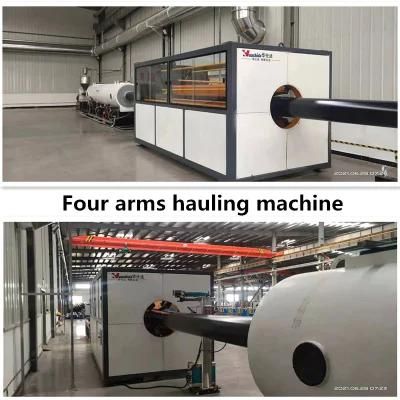

Compose of Processing Line

1. Automatic Vacuum Feeding

2. Drying Machine

3. single screw Extruder

4. Mold

5. calibrating

6. vacuum calibrating water tank

7.Hauling Machine

8. Cutting Machine

9. Carrier

10. PLC Aotumatic Control System

Main Specifiction:

| Style | PE-110/600 | PE-365/760 | PE-655/1380 | PE-960/1680 |

| Main extruder | SJ-75/33 | SJ-90/33 | SJ-120/33 | SJ-150/33 |

| Pipe diameter | Φ110-600mm | Φ 365-Φ 760 mm | Φ 655-Φ 1380 mm | Φ 960-Φ 1680mm |

| Capacity | 250-300kg/h | 400~500 kg/h | 850~950 kg/h | 900-1100kg/h |

| Installed power | 160kw | 420 kw | 480 kw | 580kw |

| Length | 35m | 36 m | 40 m | 48m |

Guarantee and after service

The guarantee period is 12 months from the date of installing, but no more than 14 months from the date of delivery. After this period we are obliged to provide with lifelong service at the expense of Buyer.

During the warranty period we are responsible to provide trouble shootings and help the customer to solve the problems, provide spare parts which are broken, except breakings caused by the Buyer.

We will provide the technical service train the workers from the buyers for free.

We can also send technicians to the buyer's companies abroad for help installation and testing the lines. But the buyer shall pay for the round trip tickets, accommodation, transportation, medicine treatment and insurance of the technicians in foreign countries and some salary accordingly.

Our Team

Our international trading show

Clients visit Huashida Insulation pipe extrusion line factory

Clients visit Huashida Insulation pipe extrusion line factory