Plastic Recycling Extrusion Machine Plastic Extruder

Sichuan Union Technology Co., Ltd.- Type:PP Strapping Band Production Line

- Plastic Processed:PP

- Product Type:PP Extruder

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:YZJPP ZQD1-IV

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Producti Width:10-15mm

- Producti Thickness:0.7-1.4mm

- Max Capacity:100kg,H or Customization

- Warranty:12 Months

- Voltage:Customer Standard

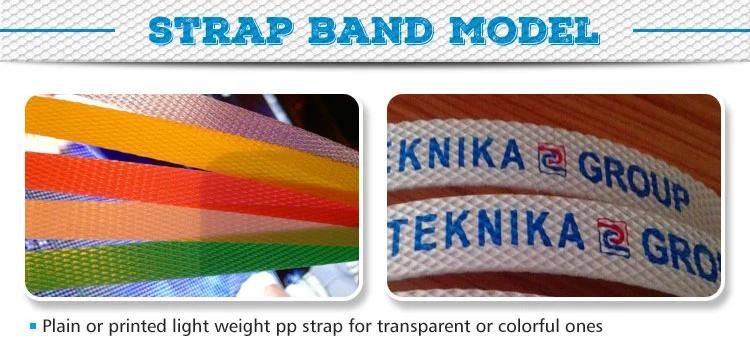

- Color:Customized

- The Brand of Electronic Component:Omron or Schneider or Delixi or Else

- Service:Free Installing and Training

- Transport Package:Pallet or Wooden Box Package

- Specification:22*6*6.5m

- Trademark:YZJ

- Origin:Sichuan

- HS Code:8477800000

- Production Capacity:10 Sets,Month

Description

Basic Info.

Model NO. YZJPP ZQD1-IV Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Producti Width 10-15mm Producti Thickness 0.7-1.4mm Max Capacity 100kg/H or Customization Warranty 12 Months Voltage Customer Standard Color Customized The Brand of Electronic Component Omron or Schneider or Delixi or Else Service Free Installing and Training Transport Package Pallet or Wooden Box Package Specification 22*6*6.5m Trademark YZJ Origin Sichuan HS Code 8477800000 Production Capacity 10 Sets/MonthProduct Description

Strap Band Belt Extrusion Extruding Machine Making Steel Strapping Production Line

Thin strap making machine

Main advantages of our PET strap making machine

1. Professional factory: We, not only produce PET & PP strapping band making machine ,but also produce PET & PP strapping band for more than 23 years. We are expert to know how to design the machine rationally.

2. Reasonable Price: We produce PET strapping band making machine and PET strapping band in large quantities. Cause large-scale operation, for the same category and same quality machine, our price is most competitive, 10%-20% lower than others.

3. High output: For the same category and same quality machine, the capacity of our machine is 20% higher than others.

4. Good quality: The width deviation, thickness deviation, skewness of straps made by our machine, is 10-20% better than others.

5. Low power consumption: 10-20% lower than others.

6. Free installation & training: quickly solve after-sales problems within 24 hours.

Our equipment can produce fully automatic packing belts, semi-automatic packing belts and manual packing belts, which can be used in one machine to meet different market demands.

What are the main configuration and technical parameters of your equipment?

| Model | YZJPP ZQD1-IV |

| Mainly applicable raw materials | PP |

| Number of straps | 1 |

| Line speed (m/min) | 180 |

| Extrusion capacity(kg/h) | 100 |

| Width of straps (mm) | 10,12,13.5,15 |

| Thickness of straps (mm) | 0.7-1.4 |

| Deviation of width (mm) | ±0.6 |

| Deviation of thickness (mm) | ±0.07 |

| Screw material | 45# carbon steel |

| Barrel material | 45# carbon steel |

| Material of cooling tank | Q235 carbon steel |

| Motor power (KW) | 70 |

| Production line (M) | 22 |

Related Products

Company Information

Sichuan Union Technology Co., Ltd. is located in the beautiful scenery along the Tuojiang River in Ziyang, Sichuan,Acquisition of "YZJ" Machinery Manufacturing Resources and Technology for more than 20 yearsThrough unremitting exploration and rapid development,Mainly involved in plastic packaging belt production equipment, waste plastic recycling equipment and plastic products and other fields,She is a "plastic machinery as the main, plastic products, theory and practice combined", research and development, production, sales in one of the scientific and technological companies.The company has research and development department, technical department, trade department, production department, property control department, finance department and so on.

The headquarter of the company consists of provincial enterprise technology center, quality center, production center, assistant engineer of the company and senior engineer personnel. The proportion of undergraduate degree and above is 62.8%.

Company size in the domestic peer enterprises in the forefront, the company covers an area of nearly 70000 square meters. Mainly involved in plastic machinery, plastic products, industrial parks, international trade, renewable resources and other fields, the annual output value of hundreds of millions of yuan, is a "plastic machinery and plastic products series as the leading," set research, production, Integrated Plastics Co., Ltd.

What's the deal process?

Test equipment to factory -> confirm equipment performance index-> pay deposit-> equipment production complete performance confirmation-> to factory site operation training, to delivery-> installation and commissioning, technical guidance

1.Pre-sale service (PET packing tape sample testing, return on investment analysis, product cost budget, provide samples (freight is borne by the customer), equipment required for on-site testing to the plant)

2.Sale service (free of charge to our customers for training production management, operational skills, process formulation, machine maintenance, enterprise system management training services)

3.After-sale service (installation of commissioning equipment, training of operators, 24-hour technical consultation, maintenance of lifelong equipment (paid out of warranty), technical upgrading, long-term technical guidance, formula verification and other services)

Packaging & Shipping

FAQ

1.How long is the delivery time of the equipment?

A: In the case of standard configuration, the equipment is delivered within 60 working days.

2.What is the chargin for equipment installation and commissioning?

A:Free installation and traning, but buyer need afford the travel around tickets ,visa fees and accommodation of the technician.

3.Is there a charge for the on-site operation training?

A:No , it is free.

4.Can your equipment be upgraded in the future?

A: Yes, it can be upgraded

5.How to solve if equipment any problem happen ? How long it will take?

A: first, communicate with our engineers through the email ,phone and video etc. If the communication still cannot be solved, we will send the technician to the customer site within 48 hours

6.If I buy your equipment, can I buy accessories for a long time?

A:Our wearing parts are stocked to ensure that the production is not delayed.

7.Are you trading company or manufacturer?

A:We are a direct manufacturer, and we have the export right , we can export ourselves.

8.How is the payment?

A: We accept T/T ,L/C ,D/P ,D/A ..... etc variety payment way.and also trade insurance by alibaba.

If you are involved in this industry for the first time, please send us an enquiry, we provide an investment analysis for your reference.