PP Strap Band Production Line (SJ-90/30) Factory Price CE Certification

Qingdao Weier Plastic Machinery Co., Ltd.- After-sales Service:Provide Technical Support

- Warranty:Factory Price CE Certification

- Type:Profile Extruder

- Plastic Processed:PP

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:SJ-90,30

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Machine Size:22m X 2m X 3m

- Machine Color:Gray+Yellow

- Certificate:CE,SGS

- Transport Package:Export Package

- Specification:CE, SGS, ISO9001

- Trademark:WEIER

- Origin:China

- HS Code:84772090

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. SJ-90/30 Assembly Structure Separate Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Machine Size 22m X 2m X 3m Machine Color Gray+Yellow Certificate CE,SGS Transport Package Export Package Specification CE, SGS, ISO9001 Trademark WEIER Origin China HS Code 84772090 Production Capacity 100 Sets/YearProduct Description

PP strap band extrusion line: (for packages)Character :

It use single screw or double screw according to your requirement

It use 100% recycling material

Measurement pump ensure constant and stable production

Two pull four station filter can efficiently eliminate impurity

Large hauling force stretch device and insulation ove

Extruder Model | Width/mm | Output Bands | Capacity kg/h |

SJ-65 | 5-19 | 1-2 | 60-90 |

SJ-90 | 5-19 | 2-4 | 150-200 |

SJ-120 | 5-19 | 4-8 | 300 |

1. It can use single screw or double screw according to your requirement. It can use 100% recycling material.

2. Even plasticization and table extrusion, PLC automatic control

3. Measurement pump ensure consecutive and stable production

4. Two pole four station filter can efficiently eliminate impurity

5. Large hauling force stretch device and insulation oven

6. Large capacity stainless steel water tank, automatically water level control.

This plastic mahcine PP strap band product for packaging. This line is comparatively low cost. The line speed is 80m/min. The width and thickness of the strap band is adjustable.

PP Bale Strap Machine is a renewed and improved design, and is special for producing the polypropylene packing strip.

The whole machine includes the extruder, mould, cooling tank, haul-off device, embossing device, winder and electrics controlling part.

The screw is with the special design and treatment and can ensure the excellent strip quality.

The whole equipment has the advantages of high capacity, excellent plasticization, strong processing adaptation, easy operation and overhaul.

Every technical index reaches the international developed level

Strap size can be from 6-19mm. Output is around 60-100kg/hr

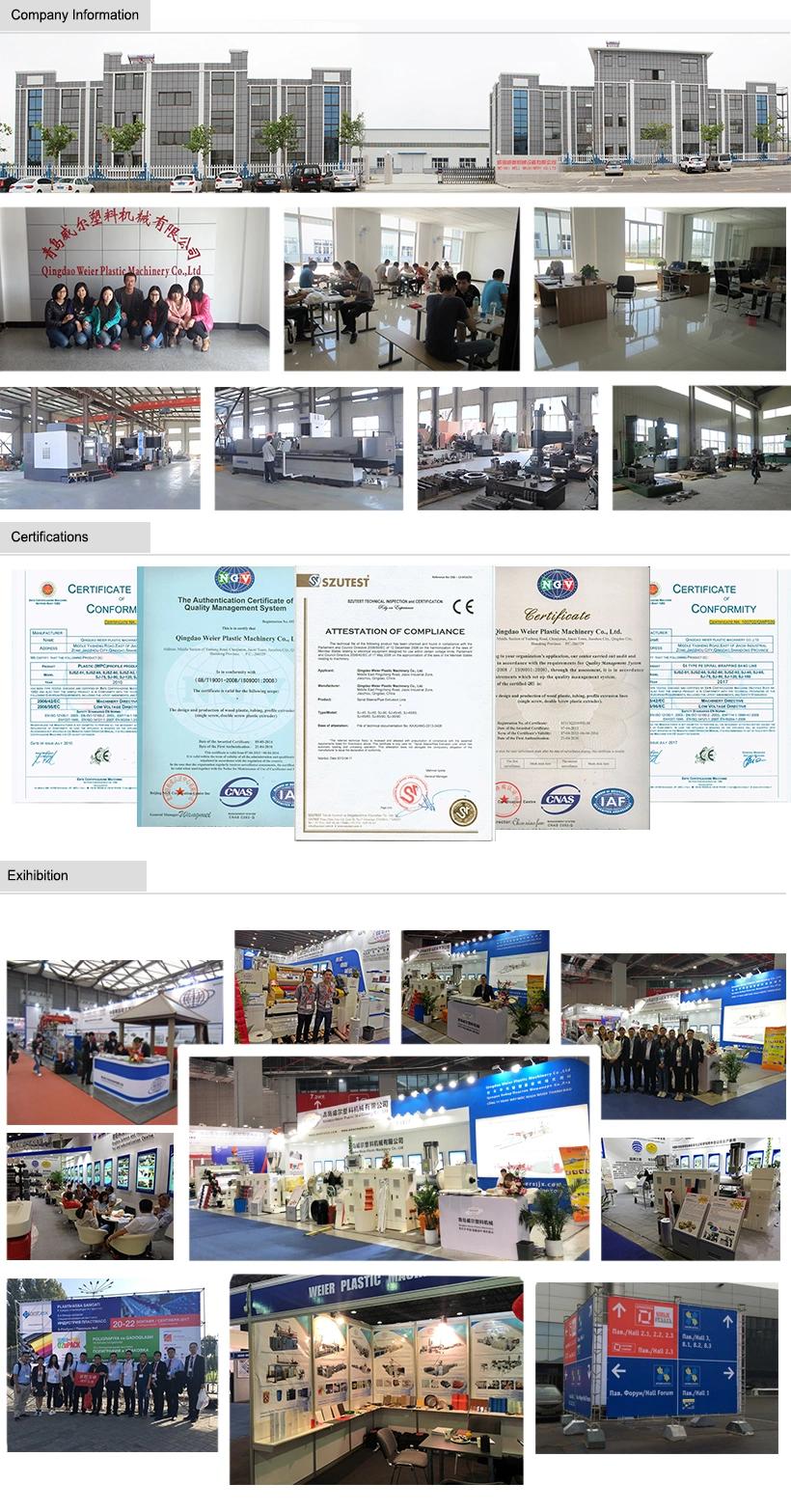

Why choose Weier?

We supply all the technical support, such as engineers, drawings, and instruction manual.

We send one or more than one engineers to client for installing and adjust all the machinery

Buyer also can sent workers to our workshop for learning how to conduct Plastic extruder

Supply formula guide service and staple raw material purchase.

We could supply the Feasibility Analysis Report for the project.

We could supply turnkey project to you.

We have good reputation from our customers both at home and abroad.