Double Head High Frequency Welding Equipment for Thick Tarpaulin (HR-25KW-2C)

Dongguan Hipower Ltd.- Color:Blue or Customize

- Transport Package:Wooden Case for Export

- Specification:CE

- Trademark:HIPOWER

- Origin:Shenzhen

Base Info

- Model NO.:HR-25KW-2C

- HS Code:8515900090

- Production Capacity:500 PCS,Year

Description

Application:

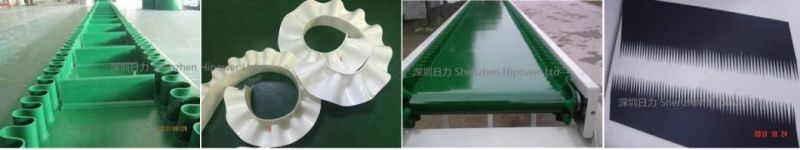

Specialize for welding and join treadmill, conveyor belt, side wall and other kinds of PVC composed plastic material.

Character

Machine General Features:

1. Single head with 600~800mm length welding area.

2. European-model squareness high frequency vibration box, more realiable and stable in output.

3. Adopting high sensitive anti-sparkle device to avoid damaging the mould from flash.

4. Install with Toshiba electron tubes.

Certifications

After Sales Service

a) Customer's site installation, training & maintenance available

b) 3 to 24 hours Online service by Email, Fax, Video Online for basic setup and repairs

c) 12 months warranty for machine, life-long tech. support

d) Recommend equipment of top choice based on your requirements for product;

e) Examining mold drawings on your behalf to confirm optimum structure size meeting the requested process;

f) Providing assistance in manufacturing and modifying tools;

g) Our engineering instruction will guarantee your productive manufacturing of top-quality products.

FAQQuestion 01: Are a trading company or Manufactuer?RE: Since 2000, we are the manufacturer in this filed;Our factory can design, develop and manufacture ODM and OEM equipments for clients all over the worlds.

Questions 02: What about Delivery Time:RE: 3 days for standard machine; and 15 to 35 days for custom machines

Questions 03: Payment Term:RE: We accept payment by T/T, L/C, West Union, Paypal.

Questions 04: How do I inspect your machine quality?RE: We always have real machines ready in stock, We shall meet you at airport, hotel, or railway station.

Questions 05: Is the machine easy to use and maintain in future?RE: Yes, it is; we shall provide instructional manual, videos and engineer support via email or video talk online.

Questions 06. How Do You Pack the machines

RE: Our machines will be packed into after treatment wood box

Questions 07. Does the machine power voltage meet buyers' factory power source?

RE:Frequency: 50 - 60HZ Phases: single phase / 3 phases ; Voltage: 110V / 220V / 380V/ 415V/ 440V / On request

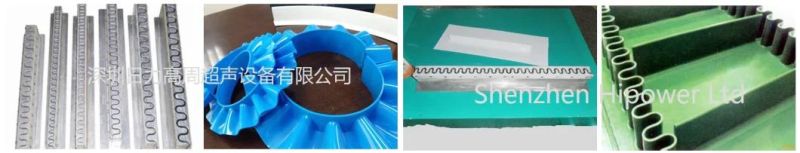

Questions 9. Could you make die / mould for me, if I buy machine from you?

RE: We design and make moulds up to product sample or drawings, we charge the mould price at facory cost price.