Multi Station Plastic Blister Vacuum Forming Machinery

Zhejiang Hongyin Machinery Co., Ltd.- Automation:Automatic

- Raw Material:PP, PVC, Pet, PS, HIPS

- Shaping Mode:On Molding

- Application:Machinery & Hardware, Food & Beverage, Medical, Toys, Chemical, Plastic Box,Bowl,Tray,Lid,Container

- Driven Type:Electric

- Computerized:Computerized

Base Info

- Model NO.:DB-72,76

- Certification:CE

- Max. Forming Area:760*720mm

- Thickness of Sheet:0.2-1.5mm

- Max. Forming Depth:80mm

- Warranty:1 Year

- Power Supply:AC 380V, 50,60 Hz

- Dimension:L9200*W2850*H2660mm

- Transport Package:Wooden Case

- Specification:720*760mm

- Trademark:HongYin

- Origin:Ruian

- HS Code:847780000

Description

Basic Info.

Model NO. DB-72/76 Certification CE Max. Forming Area 760*720mm Thickness of Sheet 0.2-1.5mm Max. Forming Depth 80mm Warranty 1 Year Power Supply AC 380V, 50/60 Hz Dimension L9200*W2850*H2660mm Transport Package Wooden Case Specification 720*760mm Trademark HongYin Origin Ruian HS Code 847780000Product Description

DB-72/76 Negative three station vacuum forming machine

Application Area:

This machine is suitable for forming HIPS, PS, PP, PVC, PET, sheet that can produce boxes, trays, fast food boxes, dishes, lids, cookies tray, egg tray, mobile phone tray & other blister tray.

Technological process

Carrying material(cylinder drives the chain to work)---heating(cylinder drives the electric furnace to lift in order to make a proof)---pulling( cylinder drives the chain)----lifting the lower die, falling the upper die(cylinder drives)-vacuum forming(vacuum pump air admission )---cooling(gas drives the spray gun to work, electric machinery drives the air blowing)----drawing of patterns(gas drives)---pulling-cutting---stacking on the line ,

Main feature

1. Whole machine adopts PLC to control the production technical process, tail remember of modern computer

2. It adopts cylinder verticality pulling-sheet design. High speed pull sheet to shorten the time. As a result it saves electricity to assure the quality of molding.

3. Heater adopts infrared ceramic heating bricks. Each heating brick has itself solid regulator to control temperature, saving more than 50% electricity compared with the traditional machine.

4. Electric stove adopts enclosed heating device to uniform heat and it can reduce the heat consumption. It is also installed with manual switches to control the verticality lifting of the electric stove which can benefit the control and assurance of during the production process.

5. The machine is equipped with wind cool, water cool chasIs and high speed cold water spraying device to speed up molding in order to assure the quality of moldings.

6. its can adopt very simple mould on this machine , save mould cost

7.negative forming is easy for operate and good for people control,

Main Technical Parameters:

| Max Forming area | 720*760mm |

| Material | PET,APET,PP,PS,PVC,ABS |

| Material thickness | 0.2-1.8mm |

| Forming height | 0-80mm |

| Production speed | 200-600times/hour |

| Mould-up times | 1 or 2 times(free to install) |

| Mould-up move | Electromotion |

| Eject-die | Shake to mould-down |

| Overall power consumption | 25kw/hr |

| Vacuum pump power | 4.0 KW/150m³ |

| Servo motor | 3kw |

| Power | 380V 50HZ |

| Air consumption | 6.5kg/cm 1000-1500Liter /min |

| Chiller power | 3HP |

| Overall diameter | (L)9200*(W)2850*(H)2660mm |

| Weight | 9200kg |

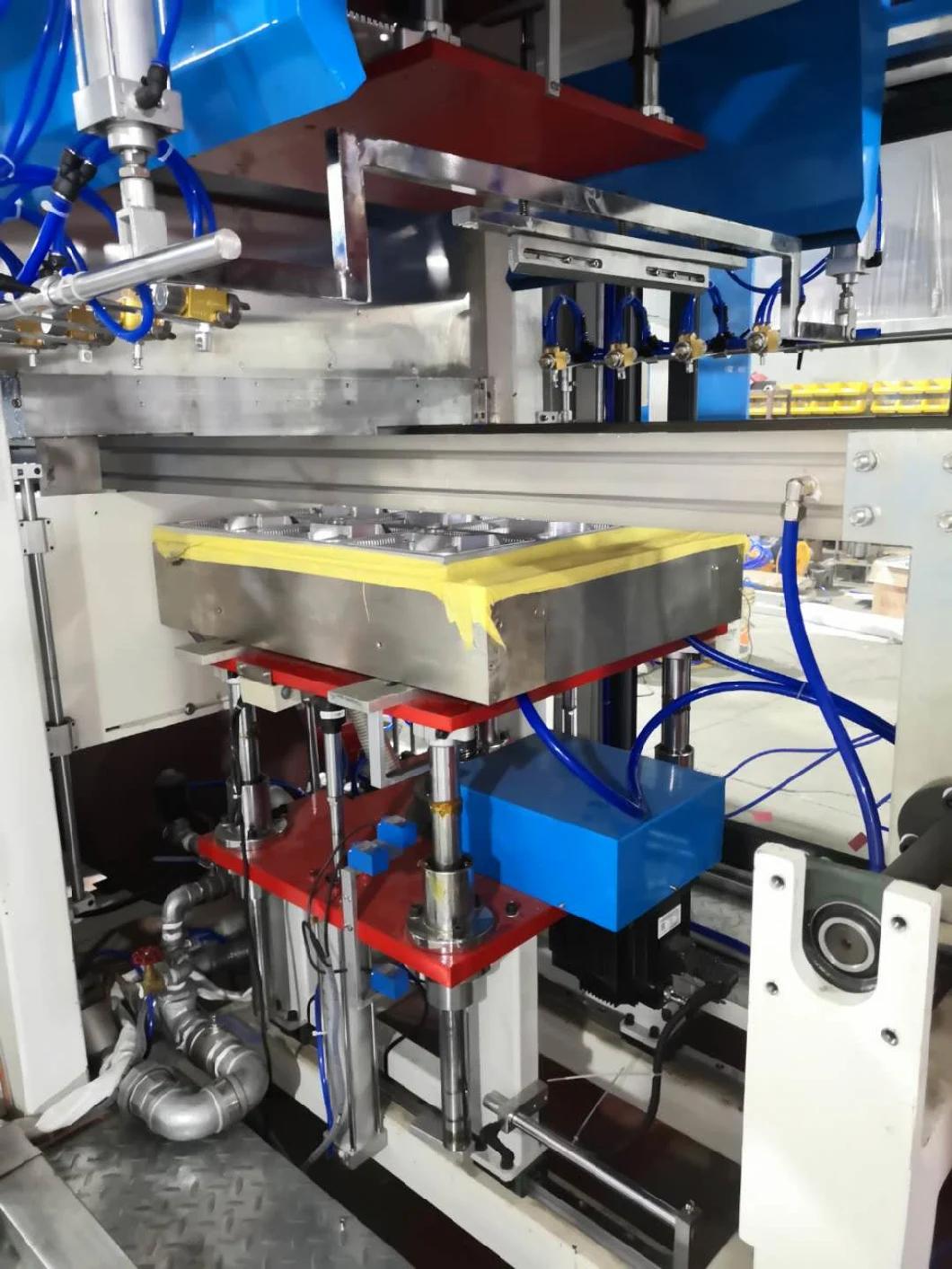

Machine showing in workshop

Forming station

Forming and cooling

Cutting station table

Cutting station table

Cutting station

Stacking and counting station

Stacking and counting station

About Zhejiang Hongyin Machinery Co., Ltd Service.

1. Purchase Service

Zhejiang Hongyin Company has a specialized and efficient working team. If you are new on the printing and packing area, some samples of your products shown to us will be appreicated, and we will give you professional suggestions of whole work.

2. Installation Service

Hongyin company will assigned 1 technician to coordinate installation, commissioning and training. Cost for return flight and suitable accommodation will be charged, and the allowance is USD100 per day.

3. Warranty Service

12 months limited warranty.

Starting from the date of machine arrival buyer's place excluding wear parts.

Shipping cost for easy broken parts to be replaced during warranty period have to be borne by the customer.

If you are interested in our machine, please feel free and contact me.

Contacter: Michael Rao