PP Nonwoven Face Mask Cloth Melt Blown Fabric Making Machine

Jiangsu Faygo Union Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:FGS45

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Wood Pallet

- Specification:FGS45

- Trademark:Faygo Plast

- Origin:China

- HS Code:84778000

- Production Capacity:100set Per Month

Description

Basic Info.

Model NO. FGS45 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Transport Package Wood Pallet Specification FGS45 Trademark Faygo Plast Origin China HS Code 84778000 Production Capacity 100set Per MonthProduct Description

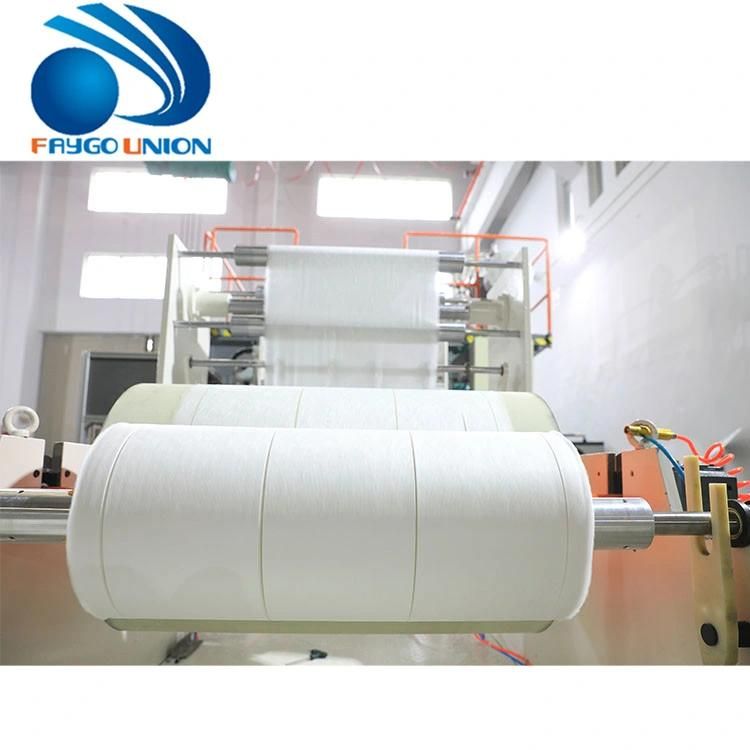

PP Nonwoven Face Mask Cloth Melt Blown Fabric Making Machine

PP Meltblown cloth is the core material of masks. Meltblown cloth mainly uses polypropylene as the main raw material, and the fiber diameter can reach 1 to 5 microns. There are many voids, fluffy structure and good anti-wrinkle ability. Ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filterability, shielding, heat insulation and oil absorption. Can be used in the fields of air, liquid filter materials, insulation materials, absorbent materials, mask materials, thermal insulation materials, oil-absorbing materials, and wiping cloths.

Application

(1) Medical and sanitary cloths: surgical gowns, protective clothing, disinfection cloths, masks, diapers, women's sanitary napkins, etc .;

(2) Fabrics for home decoration: wall stickers, tablecloths, sheets, bedspreads, etc .;

(3) Clothing fabrics: linings, adhesive linings, flakes, styling cotton, various synthetic leather backings, etc .;

(4) Industrial fabrics: filter materials, insulation materials, cement packaging bags, geotextiles, covering cloths, etc .;

(5) Agricultural fabrics: crop protection cloths, seedling cloths, irrigation cloths, insulation curtains, etc .;

(6) Others: space cotton, thermal insulation materials, linoleum, smoke filters, tea bags, etc.

Technical parameter

| Model | FGB600 | FBG1200 | FBG1600 |

| Available width: | 600mm | 1200mm | 1600mm |

| Extruder | SJ55 | SJ75 | SJ90 |

| Availbale Raw Material: | Polypropylene | Polypropylene | Polypropylene |

| Fiber diameter: | 2-5μm (micrometer) | 2-5μm (micrometer) | 2-5μm (micrometer) |

| Porducts GSM : | 15GSM-80GSM | 15GSM-80GSM | 15GSM-80GSM |

| Production line speed : | ≤80m/min | ≤80m/min | ≤80m/min |

| Max.Capacity : | 350kg / day | 600/ day | 1200kg / day |

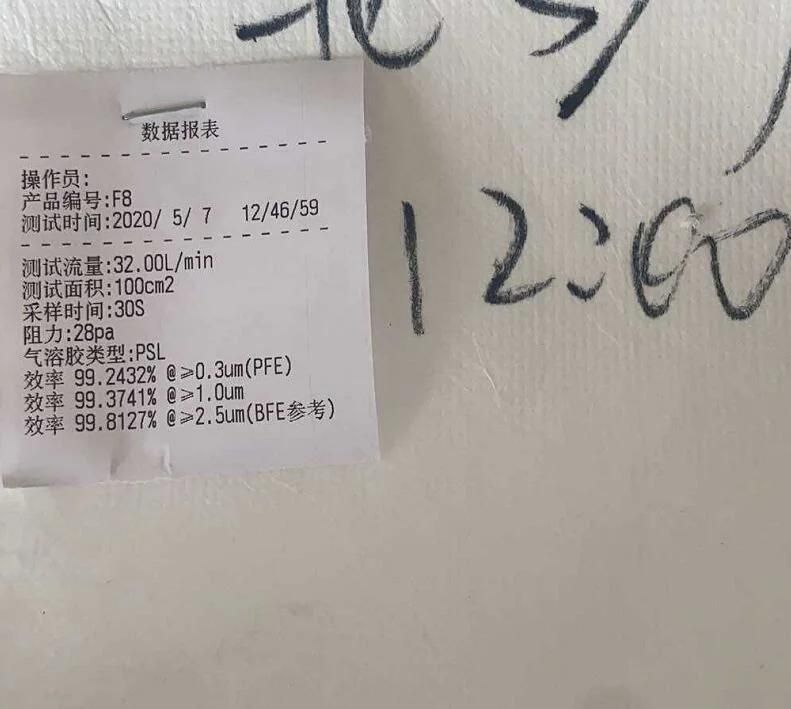

Meltblown cloth filter material is adhered together by random distribution of polypropylene ultrafine fibers. The appearance is white, flat and soft. The material fiber fineness is 0.5-1.0μm. The random distribution of fibers provides more thermal bonding between fibers. Opportunity, so that the melt-blown gas filter material has a larger specific surface area and a higher porosity (≥75%). After high-pressure electret filtration efficiency, the product has the characteristics of low resistance, high efficiency, and high dust holding capacity.