Highe Speed High Capacity 4 Cavities 16-32mm PVC Pipe Machine with Price

ZHONGSHAN YOUTH PLASTIC MACHINERY CO., LTD.- After-sales Service:Anytime

- Warranty:One Year

- Type:Pipe Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:CTS65

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Capacity:100-450kg,H

- Pipe Size:16-400mm

- Fuction:PVC Pipes

- Speed:3-20m,Min

- Transport Package:Film

- Specification:15-25meters

- Trademark:YOUTH

- Origin:China

- HS Code:8477209000

- Production Capacity:1000set,Year

Description

Basic Info.

Model NO. CTS65 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Capacity 100-450kg/H Pipe Size 16-400mm Fuction PVC Pipes Speed 3-20m/Min Transport Package Film Specification 15-25meters Trademark YOUTH Origin China HS Code 8477209000 Production Capacity 1000set/YearProduct Description

Highe Speed High Capacity 4 Cavities 16-32mm PVC Pipe Machine with Price

PVC pipe production line, we can supply different machines for diameter from 16mm to 400mm .

Produce process for PVC Pipe :

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → stacker

| Machine List for PVC Pipe Machine | Quantity |

| 1.Conical twin screw extruder (Equipped with automatic feeding unit) | One set |

| 2. Molds | One set |

| 3.Vacuum calibration unit | One set |

| 4.Haul-off unit | One set |

| 5.Cutter Unit | One set |

| 6.Stacker | One set |

| Optional auxiliary machines for your choice | |

| 1.Printer | One set |

| 2.Mixer | One set |

| 3.Crusher | One set |

| 4.Milling machine | One set |

| 5.PVC pipe belling machine | One set |

PVC 4 PIPES EXTRUSION LINE (16-32MM)

PVC four pipes (4 in 1) extrusion line is made of a 65/132 conical twin screw extruder, one set of 4 in 1 mould, one set of calibration table , haul-off & cutting combination (dust free) and stacker.The diameter of the best production tube is from16mm to 32mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc.

type | pipe diameter | capacity | Line speed | machine length |

PVC-4 | 16-32mm | 5-6tons/day | 10m/min x4 | 18m |

Screw Diameter(mm) | 65/132 | Main motor power (kw) | 37 | The height of screw (mm) | 1000 |

Direction of screws | Opposite outward ratation | Total power(kw) | 100kw | Weight (kg) | 4000 |

screw speed(r/min) | 1-37 | max output(kg/h) | 250 | boundary dimension(mm): | 4300×1500×2500 |

Effective length of the screw (mm) | 1460 | Barrel heating section number | 4 | Production line Length(m)

| 18M

|

structural style

| Cone mesh

| heating method

| casting aluminum heating | Max speed m/min

| 10m/min

|

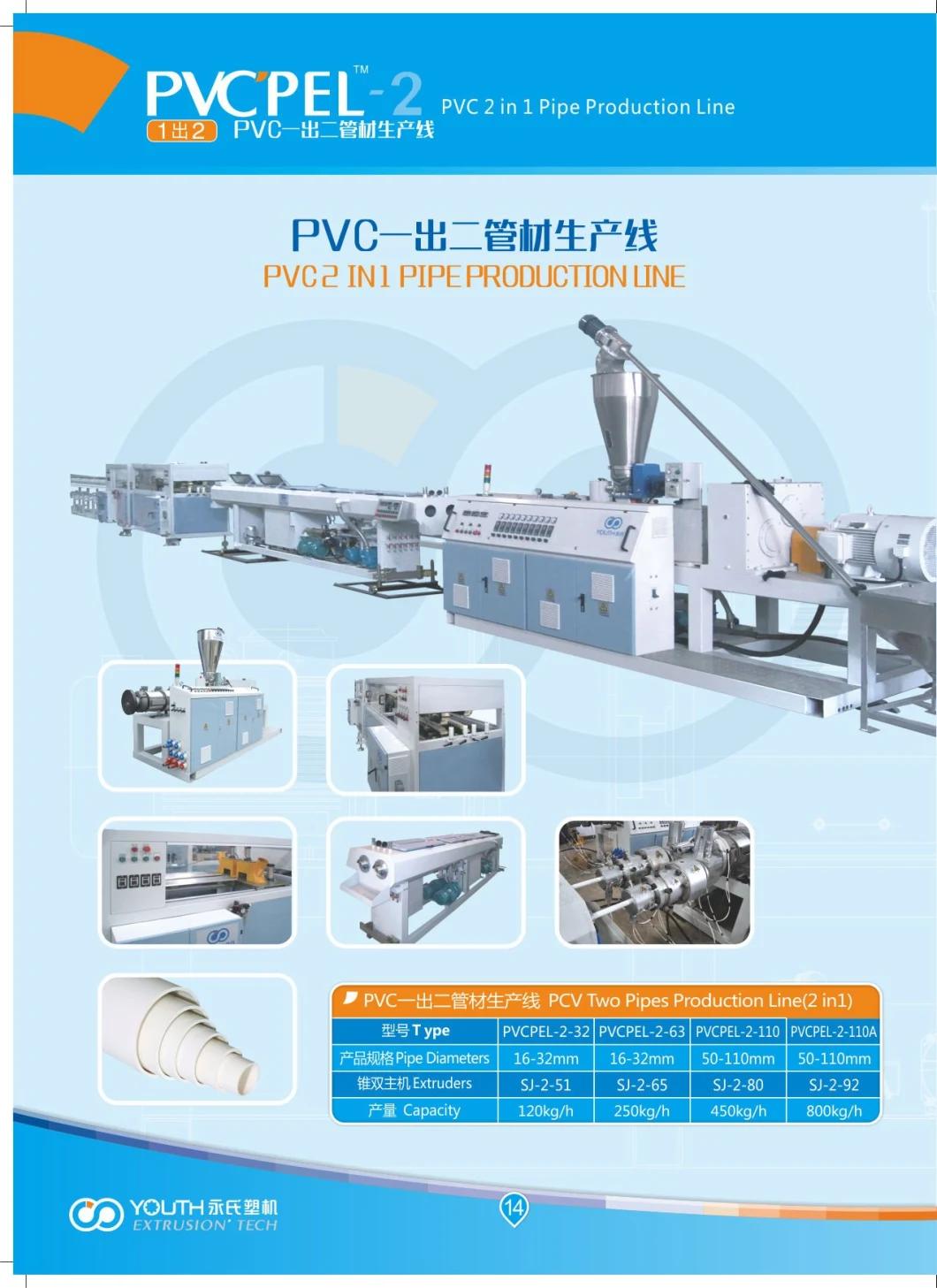

PVC two pipes (2 in 1) extrusion line is made of a 65 or 80 conical twin screw extruder, one set of 2 in 1 mould, one set of calibration table , haul-off & cutting combination (dust free) and stacker.The diameter of the best production tube is from16mm to 63mm or 75mm to 110mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc.

PVC two pipes (2 in 1) extrusion line is made of a 65 or 80 conical twin screw extruder, one set of 2 in 1 mould, one set of calibration table , haul-off & cutting combination (dust free) and stacker.The diameter of the best production tube is from16mm to 63mm or 75mm to 110mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc.| type | pipe diameter | max. output | max.line speed | machine length |

| PVC-2-63 | 16-63mm | 250kg/h | 6m/min x2 | 21m |

| PVC-2-110 | 75-110mm | 450kg/h | 7m/min x2 | 23m |

PVC single pipe (1 in 1) extrusion line is made of a 51 or 65 or 80 conical twin screw extruder, one set of 1 in 1 mould, one set of calibration table , haul-off & cutter (dust free) and stacker.The diameter of the best production tube is from16mm to 63mm or 75mm to 160mm, 200-450mm.

PVC single pipe (1 in 1) extrusion line is made of a 51 or 65 or 80 conical twin screw extruder, one set of 1 in 1 mould, one set of calibration table , haul-off & cutter (dust free) and stacker.The diameter of the best production tube is from16mm to 63mm or 75mm to 160mm, 200-450mm.Main features: high capacity, low power consumption, low water gas consumption, low occupation, low noise, low dust, etc.

| type | pipe dia | extruder | max. output | max.line speed | machine length |

| PVC-1-63 | 16-63mm | CTS51 | 180kg/h | 6m/min | 20m |

| PVC-1-160 | 75-160mm | CTS65 | 250kg/h | 5m/min | 23m |

| PVC-1-400 | 200-400mm | CTS80 | 450kg/h | 4m/min | 25m |

| PVC-1-450 | 200-450mm | CTS92 | 650kg/h | 2m/min | 30m |