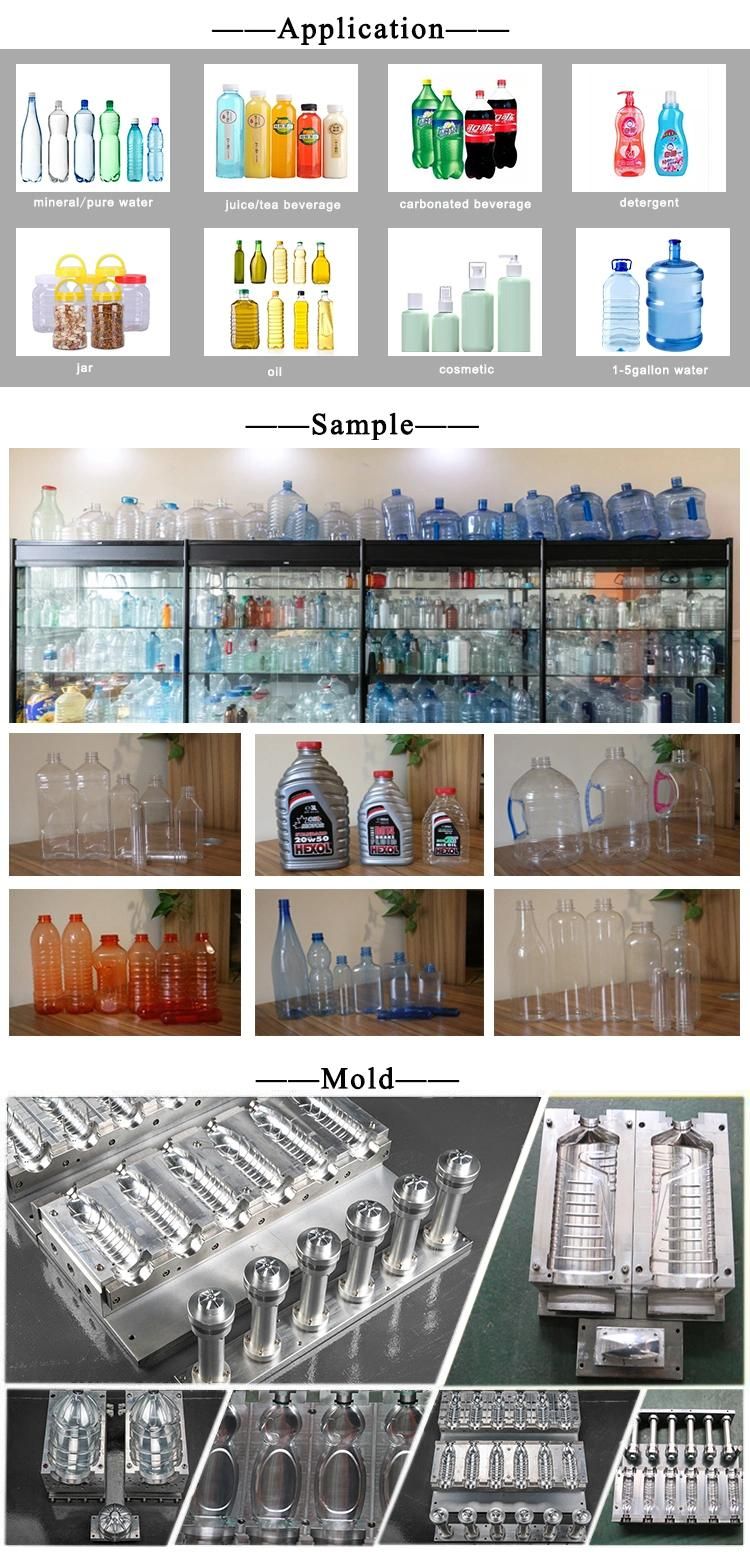

2 4 6 8 Cavity Full Automatic Pet Bottle Blowing Moulding Machine Bottle Making Machine

Zhangjiagang Eceng Machinery Co., Ltd.- Type:Stretch Blow Molding Machine

- Raw Material:PET

- Making Method of Parison:Stretch Blow

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:q6000

- Color:Orange

- Cavity:4

- Bottle Material:Pet

- Power:1.25kw

- Output:5000-6000

- Weight of The Machine:4.5ton

- PLC:Mitsubishi

- Driven Type:Pneumatic

- Transport Package:Wooden Package,According to Customer′s Request

- Specification:CE ISO SGS

- Trademark:Eceng

- Origin:Zhangjiagang Jiangsu

- HS Code:8477300000

- Production Capacity:100per Year

Description

1,Auto-loader improves working efficiency,accurate transportation,reliable and durable,raw materials are completely free of moisture,pollution,foreign matter, and loss during feeding process.Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

2,New clamping system,upgraded on the basis of the original ones,increase mould clamping speed and output,greatly reduce mold clamping noise.

3,Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; heating lamp,reflector width and height can be adjusted to suit preform heating of different structure,with automatic temperature-removal device to ensure the constant temperature of oven.

4,Q series bottle blowing machine adopts advanced microcomputer PLC control system, stable performance; servo transmission system, high positioning accuracy, fast speed, stable and reliable.

THE AFTER-SALE SERVICE OF ECENG MACHINE!

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

SEE ECENG MACHINE HOW TO ENSURE THE QUALITY!

In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

Each component before assembly needs strictly control by inspecting personnel.

Each assembly is in charged by a master who has working experience for more than 5 years

After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory