Mixer/Pneumatic Conveying System for Powder/Pneumatic Transport System/Vacuum Conveyor/PVC ...

Zhangjiagang Chiyu Automation Equipment Co., Ltd.- Applicable Material:Powder,Pellet

- Conveying Distance:up to 500meters

- Compressed Air:Required

- Material:SS304

- Transport Package:Wood Pallet+Stretch Film Package

- Specification:depends

Base Info

- Model NO.:CY

- Trademark:Chiyu

- Origin:Jiangsu, China

- HS Code:8477800000

- Production Capacity:100sets,Year

Description

Basic Info.

Model NO. CY Trademark Chiyu Origin Jiangsu, China HS Code 8477800000 Production Capacity 100sets/YearProduct Description

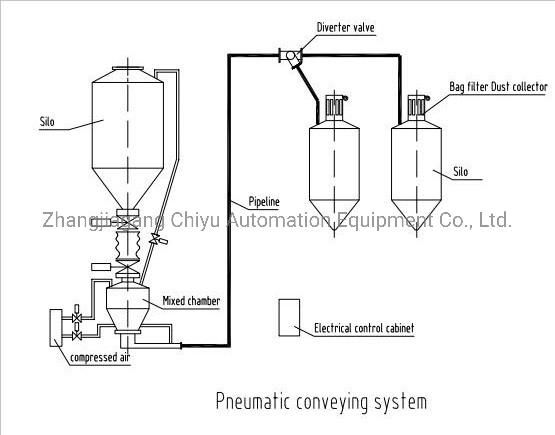

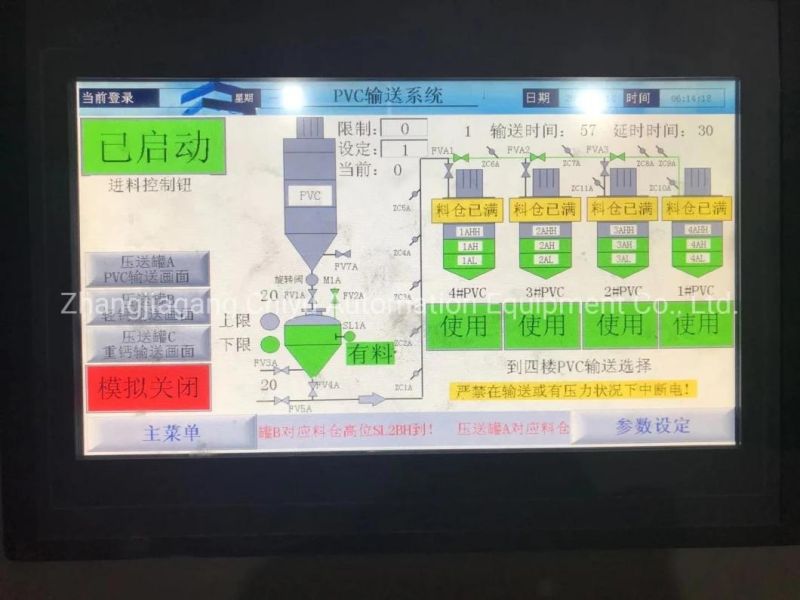

This pneumatic conveying system is specially designed for long distance big capacity conveying, it can convey up to 500meters in horizontal distance, now this high efficiency conveying system has been widely used in chemical industry, plastic& rubber industry, food industry, etc. our company has rich experience in providing system solution for powder/pellet material conveying mixing dosing handling, at domestic and abroad market, we have many succussful projects.For plastic industry:

The plastic industry was one of the first industries to recognise the benefits of pneumatic handling of material and processing, our company has designed and installed many turnkey systems for many polymar produceers and users, nowadays, this pneumatic conveying system has been adopted and used for many window & door profile factory, PVC pipe factory, SPC/LVT/WPC flooring factory, etc.

Our pneumatic conveying system characteristic:

- Extremely high efficiency

- Dust-free, closed system

- Hygienic and operator-friendly

- Space and height saving design

- Flexible configuration of pipes

- Reliable conveying

- Gentle and low-wear for product and plant

In principle, pneumatic conveying systems are differentiated in pressure and vacuum mode. A combination of these both systems is also possible.

Vacuum conveying systems

Vacuum pneumatic conveying systems are best employed where the product is to be conveyed from several feeding points to one delivery point. Product channelling is extremely simple and dust-free since there is no excess pressure

Pressure conveying systems

Pressure conveying systems are best employed where the product is to be conveyed from one feeding point to several delivery points over long distances. Since the product has to be conveyed against the air pressure, locks or pressure vessels are required. Product delivery is under atmospheric pressure and however simpler.

Vacuum pressure conveying systems

Conveying systems combining suction and pressure are best used where the product is to be conveyed from several feeding points to several delivery points.