Automatic Plastic Fork Knife Spoon Pallet Making Injection Molding Machine

Zhangjiagang Shenzhou Machinery Co., Ltd.- After-sales Service:24 Hours Online After-Sales

- Warranty:2 Year

- Type:Injection Molding

- Structure:Horizontal

- Plastic Type:Thermoplastic

- Plasticizing Way:Screw Type

Base Info

- Model NO.:130 ton

- Clamping Way:Hydraulic & Mechanical

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, SGS

- Keyword:Plastic Spoon Knife Spoon Pallet Making Machine

- Function:Multifunctional Plastic Products Making

- Motor:Servo Energy Saving

- Advantages:Energy Efficient,Long Service Life

- Operation Language:Multilingual, You Can Choose

- Color:Customers′ Request

- Price:Ex-Factory Price

- Experience:20 Years of Rich Experience

- Quality:Professional Quality Control Team

- After Sale:Product Lifetime Maintenance

- Brand:Shenzhou,China Certified Brand

- Service:One-Stop Complete Solution

- Certificate:CE;ISO;SGS

- Export Experience:More Than 15 Years

- Customer:More Than 2000

- Transport Package:Standard Export Wooden Box

- Specification:4.7*1.25*1.85m

- Trademark:SHENZHOU

- Origin:Suzhou, Jiangsu, China

- HS Code:8477101090

- Production Capacity:50sets Per Month

Description

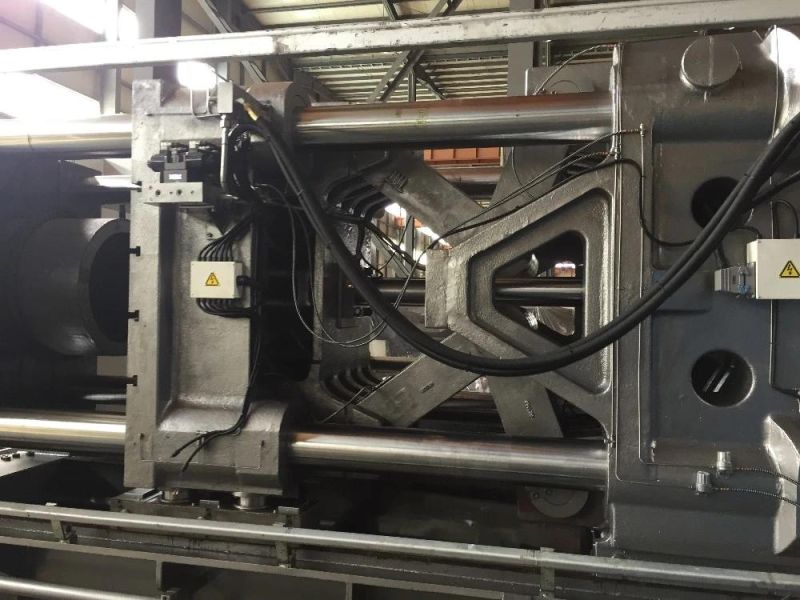

New type 5-point toggle device of stable movement curve,gentle shock.Proportional pressure and flow control with fine adjustment and precision.

New type 5-point toggle device of stable movement curve,gentle shock.Proportional pressure and flow control with fine adjustment and precision.

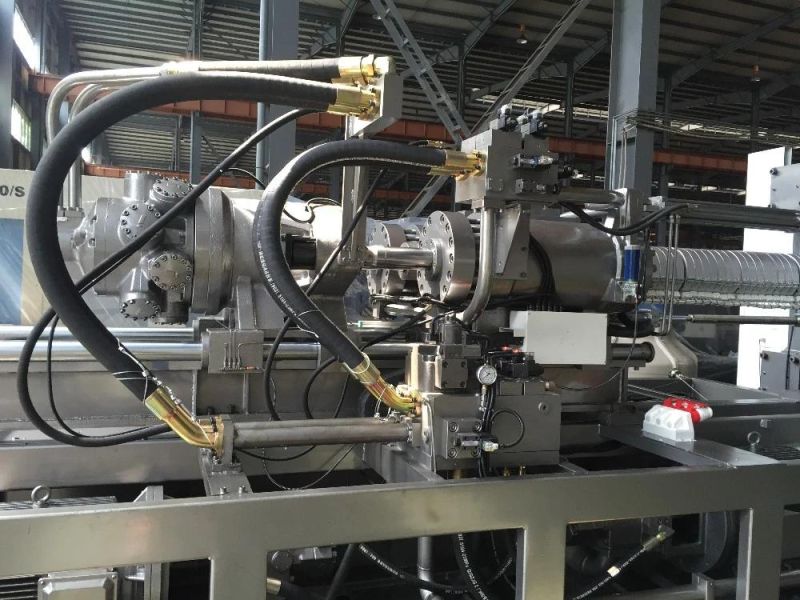

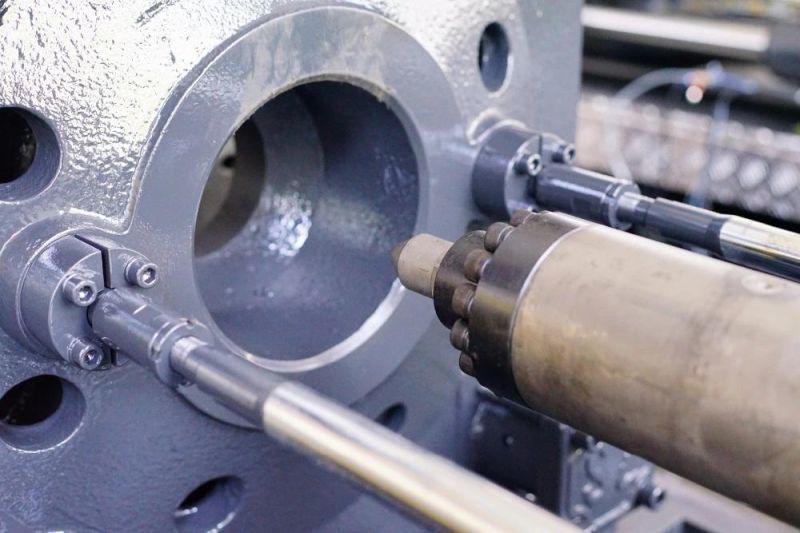

Nitrided screw and barrel with long service life.Smelted screw with big L/D ratio with good plasticizing and color-fixing.Double injection cylinder of compact construction and good equilibrant.Transducer control injection stroke.The speed of low speed and large torque hydraulic motor can be adjusted.Screw back pressure control and nozzle anti-leakage control movable hopper for easy remove material.Injection-catriage can be used for slacking,re-feedingor fixed-feeding.Speed and pressure of injecting and holding controlled by time or position.Equipped with reverse device to be easily removed and cleaned.

Nitrided screw and barrel with long service life.Smelted screw with big L/D ratio with good plasticizing and color-fixing.Double injection cylinder of compact construction and good equilibrant.Transducer control injection stroke.The speed of low speed and large torque hydraulic motor can be adjusted.Screw back pressure control and nozzle anti-leakage control movable hopper for easy remove material.Injection-catriage can be used for slacking,re-feedingor fixed-feeding.Speed and pressure of injecting and holding controlled by time or position.Equipped with reverse device to be easily removed and cleaned.

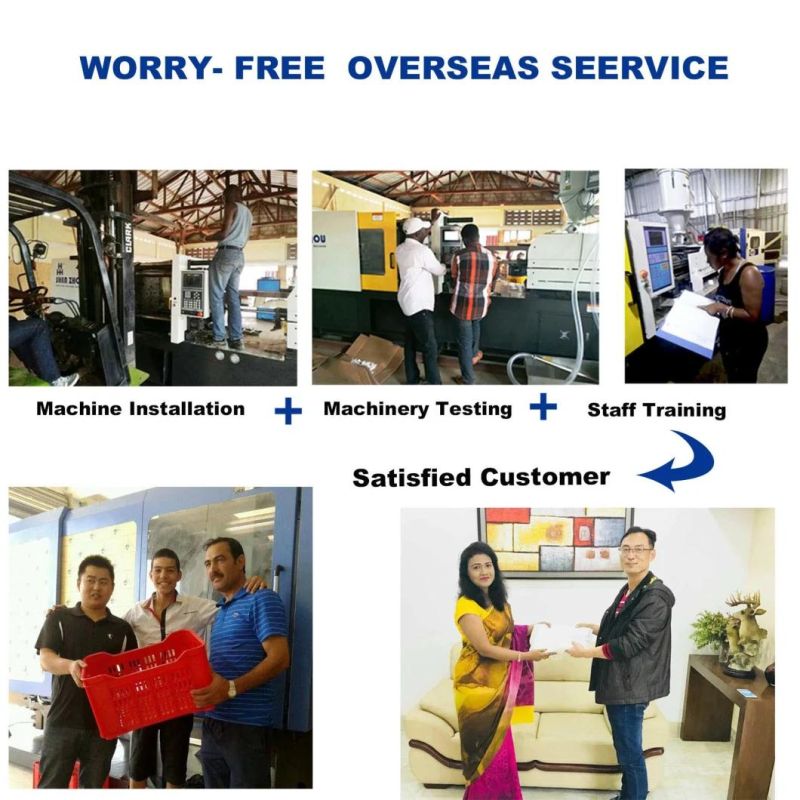

Why Choose Us

1. 20 years of professional injection molding machine and mold manufacturer, excellent quality, honest management

2. Continuous technological innovation, optimized product structure, longer service life

3. Lifetime maintenance of the product, 24 hours after-sales service

4. The main components are all world-renowned brands

5. Dedicated quality control department

6.Ex-factory price

Company Profile

SHENZHOU-Your trusted plastic processing partner

Our company - injection molding machine, blow molding machine, main blower, mold, computer embroidery machine professional manufacturer - located in the national new port city of Zhangjiagang City, Xizhang Town, close to the Yanjiang Expressway and 204 National Road, close to Shanghai, Nanjing, Suzhou, Wuxi Large and medium-sized cities such as Nantong have convenient transportation.The company has accumulated rich experience in manufacturing injection molding machines for many years, high standard design and precision processing, using imported famous brand hydraulic, electrical and sealing components, and fully creating SZ series automatic computer injection molding machine and peripheral supporting equipment, with its excellent quality and stability. The performance, superior price performance ratio, to the greatest extent to meet the interests and needs of customers.

Packing & Delivery

We will apply lubricating oil and spray anti-rust agent to the products before shipment, prepare enough spare parts, and confirm that they are fully fixed before shipment. We pay attention to details and hope to bring you a better experience.

We will apply lubricating oil and spray anti-rust agent to the products before shipment, prepare enough spare parts, and confirm that they are fully fixed before shipment. We pay attention to details and hope to bring you a better experience.FAQ

1.Q:Are you a factory or trading company?

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit !

2.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department.

3.Q:What are your normal lead times?

A:Our company typical lead times range from 25-35days after receipt of order.We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks.

4.Q:About the price?

A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions.

5.Q:How is your machine different from other businesses?

A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use.

6.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients,from home or abroad, are warmly welcome to visit us!

You are welcome to send us samples, we will customize high-quality machines for you! Best wishes for you!