Nanjing Twin Screw Extruder Machine Plastic Waste Granule Making Machine

Nanjing Kairong Machinery Tech. Co., Ltd.- After-sales Service:Online Service

- Warranty:1 Year

- Type:Screw Extruder

- Plastic Processed:Pet

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:tse series

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Keyword:Double Screw Extruder

- Contactor:Schnerder

- Output:750-1250kg,H

- Motor Power:110kw, 132kw, 160kw, 200kw

- Motor:Simens AC

- Condition:New

- Place of Origin:Jiangsu, China (Mainland)

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Transport Package:Wood Packing

- Specification:CE ISO9001

- Trademark:kairong

- Origin:Jiangsu, China (Mainland)

- HS Code:84772090

- Production Capacity:500sets,Year

Description

Basic Info.

Model NO. tse series Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Keyword Double Screw Extruder Contactor Schnerder Output 750-1250kg/H Motor Power 110kw, 132kw, 160kw, 200kw Motor Simens AC Condition New Place of Origin Jiangsu, China (Mainland) After-Sales Service Provided Engineers Available to Service Machinery Overseas Transport Package Wood Packing Specification CE ISO9001 Trademark kairong Origin Jiangsu, China (Mainland) HS Code 84772090 Production Capacity 500sets/YearProduct Description

plastic recycling twin screw extruderAdvantages of plastic recycling twin screw extruder compared with single screw extruder

Higher production capacity.

Energy and time savings as pre-drying and crystallization are omitted.

High quality of the end product which does not become yellowish.

High flexibility because formula and colors can be changed very quickly due to the good self-cleaning behavior of the plastic recycling twin screw extruder.

Much simpler logistics because pelletized new product and different regenerates can be processed together.

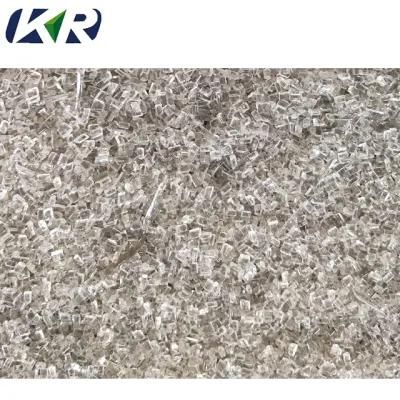

Raw material:

Raw material: If your material are like these, and you do not want to spend too much on the recycle machine. Our TSE series plastic recycling twin screw extruder can be a good choice.

Application

ApplicationMost recycling tasks make granules as a mediate product. For some materials, either pelletizing system or sheet extrusion downstream can be equipped after the plastic recycling twin screw extruder. In the case of PET bottle flakes recycling it can produce PET pellets and it can make PET sheet directly. This is a branch of our direct extrusion technology!

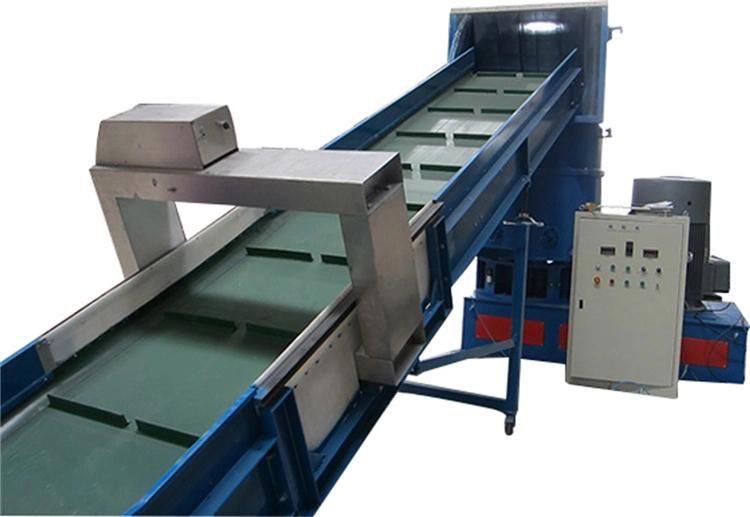

Auxiliary machines you may need:

Auxiliary machines you may need:The plastic recycling twin screw extruder line with belt conveyer, crusher, extruder, auxiliary equipment. The line with characteristics of high output, low energy dissipation, labor-force saving, and high quality pellets, is an ideal equipment for plastic recycling twin screw extruder.

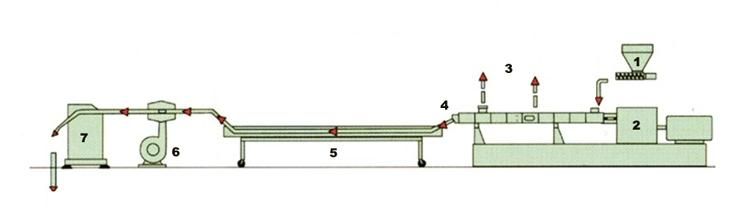

Plastic recycling twin screw extruder process

According to the cleanliness of raw materials and actual production needs, plastic recycling twin screw extruder with water ring pelletizing or strand pelletizing can be selected to match different raw materials.

1.PET raw material feeding

1.PET raw material feeding2.TSE series plastic recycling twin screw extruder

3.Degassing

4.Roots pump and special designed filter

5.Special designed water bath

6.Air blower

7.Strand pelletizer

Roots pump for Plastic recycling twin screw extruder

Compared with other types of vacuum pumps, roots vacuum pump has the following advantages:

1) There is no gas compression in the pump chamber, and there is a gap between moving parts, so it is not sensitive to dust and steam in the pumped gas, so condensable steam can be extracted.

2) The moving parts in the pump chamber do not need oil lubrication, which can avoid the pollution of oil steam to the vacuum system and is conducive to obtaining oil-free vacuum.

3) The utility model has the advantages of simple structure, low noise, no contact between moving parts in the pump cavity, no damage and low maintenance cost.

4) start quickly and reach the limit vacuum in a short time.

New design cooling and pelletizing line for Plastic recycling twin screw extruder

Special designed diehead which can effectively filter impurities

Technical data of plastic recycling twin screw extruder:

| Mode | Diameter (mm) | L/D | Screw rotary speed (r/min) | Motor power (kw) | Torque (N.m) | Capacity (kg/h) |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-300 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-550 |

| TSE-75D | 71 | 32-64 | 600 | 220-250 | 1990 | 500-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 800-1200 |