Virgin Plastic Granules Making Extruder Machine for Plastic Manufacturer

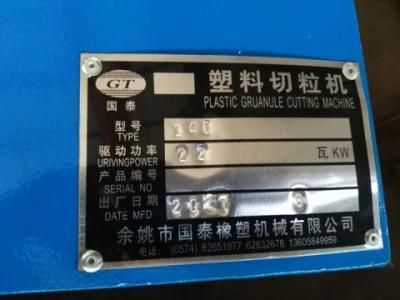

Yuyao Guotai Rubber & Plastic Machinery Co., Ltd.- Material Processed:Plastic

- Plastic Type:PVC,PP,PE,ABC

- Screw:Single-Screw

- Automation:Automation

- Computerized:Computerized

- Certification:ISO9001:2008, CE

Base Info

- Model NO.:SJ Series

- Condition:New

- Capacity:50-500kg,Hr

- Screw Daimeter:90-150mm

- Application:Plastic Film

- Use:Plastic Recycling and Granulating

- Type:Single-Stage

- Material:PP PE ABC PVC

- Brand Name:Gt

- Color:Customized

- Voltage:380V,Customized

- Transport Package:Wood Bottom Case

- Specification:CE

- Trademark:GT

- Origin:China

- HS Code:8477209000

- Production Capacity:10 Set,Month

Description

Basic Info.

Model NO. SJ Series Condition New Capacity 50-500kg/Hr Screw Daimeter 90-150mm Application Plastic Film Use Plastic Recycling and Granulating Type Single-Stage Material PP PE ABC PVC Brand Name Gt Color Customized Voltage 380V/Customized Transport Package Wood Bottom Case Specification CE Trademark GT Origin China HS Code 8477209000 Production Capacity 10 Set/MonthProduct Description

Virgin Plastic Granules Making Machine for Plastics ManufacturerMaterials processed

PVC, PE, PP, PC, PA, ABS, PS, PPR, POM, PBT, Nylon, EPS, PET and etc.

Applications and Components

1. Being used to make the plastic granules from the plastic resin and plastizer.

The complete plastic granules production line consists of high speed kneader(mixer), extruder, mould, water sink, drying blower and pelletizer.

2. Being used to recycle the plastic wastes such as, bottles, films, bags, scramps, lumps and make them into the granules.

The complete plastic granules production line consists of washing machine, crusher, extruder, mould, water sink, drying blower and pelletizer.

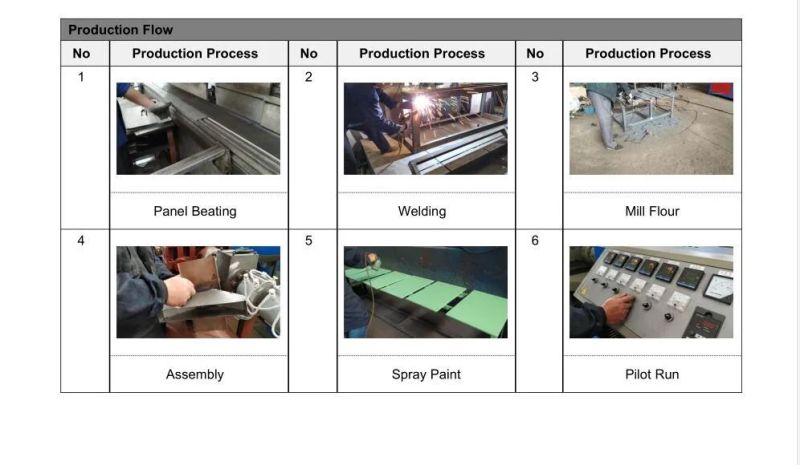

Production description

Firstly, the raw materials(crushed plastic wastes or resin) enter the screw barrel through the feed cylinder, transformed into the melt after multi-stage heating. Secondly, extruded out of the mould and enter the feed cyclinder of the another extruder, after being heated in several heating areas. Thirdly, the melt is exturded out through mould and become many strips, cooled by the water sink, through the drying blower to take away part of the water. Finally, cutted into granules by the pelletizer, that is the final product.

It adopts the two-step master and seconday structure to meet the double-layer filter purpose.It can effectively remove the impurities in the feed back and fully exhaust the gas.It can produce ample,consolidated and fine luster granules.

granulator drying machine is supplied with factory price.

plastic recycling machine Components:

Plastic recycling machine consists of the extruder, the water tank and the granule cutter. The blower can be added according to the customer's request.

plastic granulator

used hdpe ldpe recycling machine

plastic recycling machine

plastic bottle recycling and granulation machine

plastic recycling granulator machine

plastic granules making machine

plastic bottle washing machine

two stage plastic Recycling Pelletizer

pp recycling and granulating machine

plastic film recycling and granulation machine

plastic wastes recycling granulator price

cold cutting PVC granules making machine

hot cutting virgin pvc granules machine

cold cutting pvc recycling pelletizer machine

plastic recycling granulation machine

plastic flakes recycling pelletizer

PVC PP Recycling Pelletizer

Features: Well-proportioned, high out put, stable quality, wide applicable range, long serving life.

| model | screw daimeter | motor(kw) | capacity |

| SJ90 | 90 | 30 | 150-200kg/h |

| SJ105 | 105 | 45 | 180-220kg/h |

| SJ110 | 110 | 45 | 200-250kg/h |

| SJ120 | 120 | 90 | 250-300kg/h |

| SJ100 | 100 | 45 | 155-200kg/h |

FAQ

Q: Your company is a trading company or an industrial manufacture factory?

A: We are an industrial manufacture factory. We have independent technical team who focus on making machines, all the products are made by our technical team.

Q:What is the ability of your factory?

A:About 300 set per year.

Q:Do you have any other services about your products?

A:We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

Q:How do you make the quotation for clients?

A:Please offer the following information, so we can give you price and our advice as manufacturer:

1. Type of pipe you want to produce.

2. Pipe diameters.

3. Raw material and its types

If you can also send us photos of your samples, it would be highly appreciated..