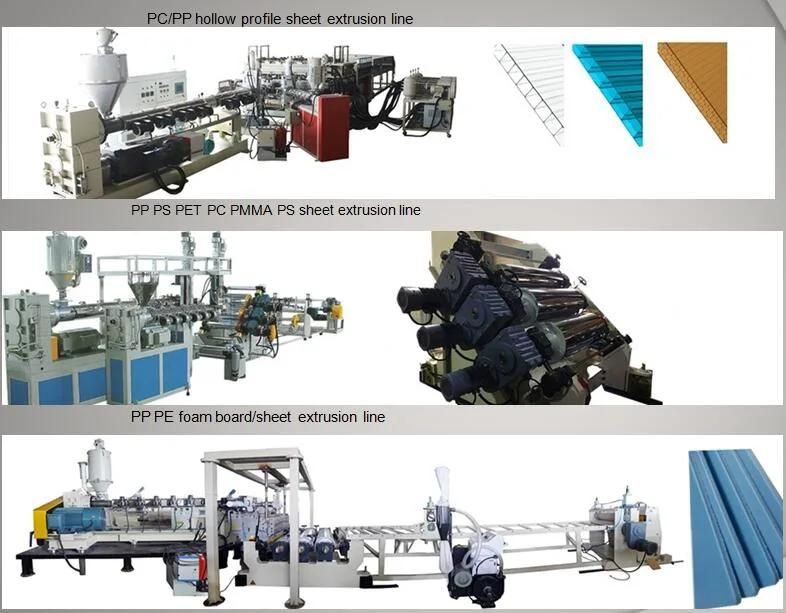

WPC Foam Board Machinery WPC Foam Board Extrusion Production Line

Qingdao Leader Machinery Co., Ltd.- Product Type:PVC Board

- Board Layers:Single Plate

- Screw No.:Double-screw

- Automation:Automatic

- Computerized:Computerized

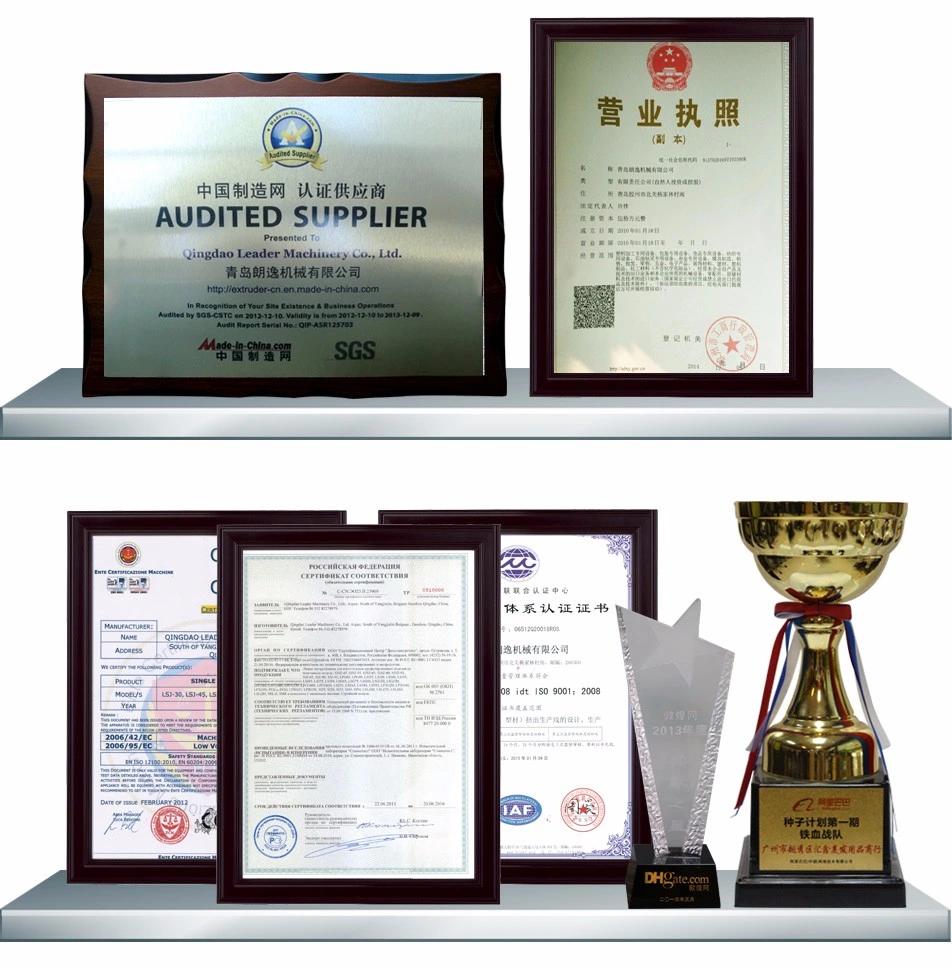

- Certification:CE, ISO9001:2008, GOST

Base Info

- Model NO.:SJSZ-80,156

- Customized:Customized

- Condition:New

- Name:WPC Foam Board Extrusion Production Line

- WPC Foam Board Size:1220mm*2440mm*3-20mm

- Application:Furniture Board, Cabinet Board, Construction Board

- Extruder Model:Conical Twin Screw 80,156

- Max Capacity:400kg,H

- Die Head:T-Type

- Main Electrical Parts:ABB, Omoron, Schnider, Delix, Rkc

- Guaranteed Time:12 Months

- Transport Package:Wooden Cases with Vacuum Film

- Specification:CE ISO9001-2008, GOST, SGS

- Trademark:Leader Machinery

- Origin:Qingdao of China

- HS Code:8477209000

- Production Capacity:20 Sets,Year

Description

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 9 CONTACT INFORMATION: