PC Polycarbonate Honeycomb Roofing Sheet Extrusion Machine

Qingdao Leader Machinery Co., Ltd.- Product Type:PC Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:LSJ-120,35+45,30

- Customized:Customized

- Condition:New

- Sheet Size:2100mm Width*4-10mm Thickness

- Application:Packing or Roofing or Construction etc

- Extruder Model:Sj120,35

- T-Die Head:Jc-Times Brand

- Main Electrical Parts:ABB, Omron, Rkc, Schneider, Siemens, Eurotherm etc

- Delivery Time:90days

- Guaranteed Time:12 Months

- Machine Dimension:39m*7m*4.2m

- After Sale Service:Engineers Are Available to Customer′s Factory

- Transport Package:Wooden Pallet,Cases with Streching Films

- Specification:LMSB-120,35

- Trademark:leader machinery

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:25 Sets,Per Year

Description

Basic Info.

Model NO. LSJ-120/35+45/30 Customized Customized Condition New Sheet Size 2100mm Width*4-10mm Thickness Application Packing or Roofing or Construction etc Extruder Model Sj120/35 T-Die Head Jc-Times Brand Main Electrical Parts ABB, Omron, Rkc, Schneider, Siemens, Eurotherm etc Delivery Time 90days Guaranteed Time 12 Months Machine Dimension 39m*7m*4.2m After Sale Service Engineers Are Available to Customer′s Factory Transport Package Wooden Pallet/Cases with Streching Films Specification LMSB-120/35 Trademark leader machinery Origin Qingdao, China HS Code 84772090 Production Capacity 25 Sets/Per YearProduct Description

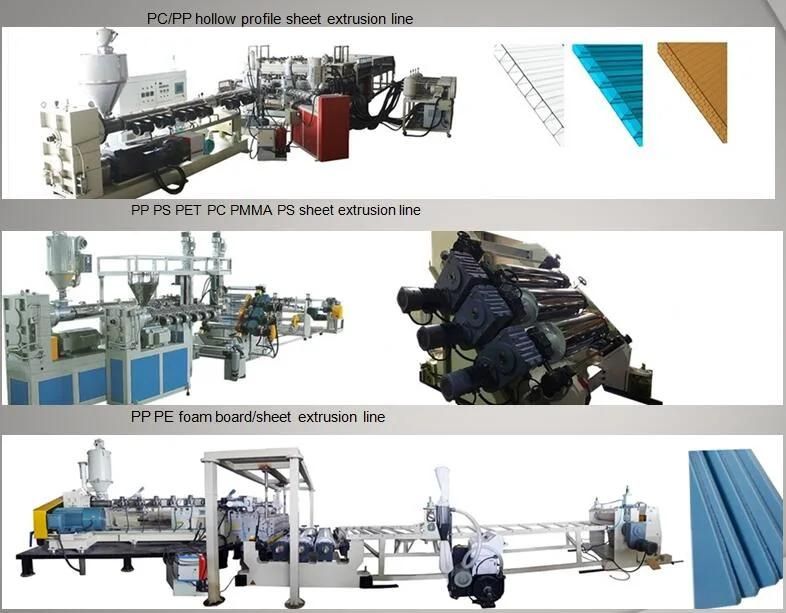

pc/polycarbonate honeycomb roofing sheet extrusion machineThis pc hollow sheet extrusion line uses high speed energy-saving stable screw, capacity increased by more than 25% compared to similar products; special design calibrating device, each individual control; specific temperature control device, reduce heat shrinkage, simple operation. The hollow sheet is characterized by light weight, high intensity,high transparency damp proof, and anticorrosion.

The technology of hollow sheet die with co-extrusion feed block to get UV+PC+UV, UV+PC hollow sheet can save 30% UV on the surface.

Hollow Sheets Specifications:

Sheet width: 600mm-700mm-1050mm- 1220mm-2100mm-2300mm,

Sheet thickness is 4mm-6mm-8mm-10mm-12mm.

Sheet walls: double walls , three walls, 4 walls and more etc.

Polycarbonate hollow sheets applications:

1.Sunshades for stadium and bus shelters

2.Lighting for corridors, passages and subway entries

3.Bank ATMs

4.Sound and heat insulation for construction such as: houses

5.Canopies for agriculture greenhouse, zoos

6.PC sheets mainly used for building and decorating materials, greenhouse material, telephone booth, insulation shield express ways & highways

7.Office building, hotels, villas, stadium, schools, bus stop, terminals, hospitals, subway entry and exit doors, etc.

Part 4 Main Data for the Machine

| Main extruder screw diameter | 120mm |

| L/D | 35:1 |

| Main motor power | 185kw |

| Co-extruder screw diameter | 45mm |

| L/D | 30:1 |

| Motor power | 15kw |

| Sheet thickness range | 4-30mm |

| Sheet width | 2100mm |

| Capacity | 200-350kg/h |

| Actual running power consumption | 200kw |

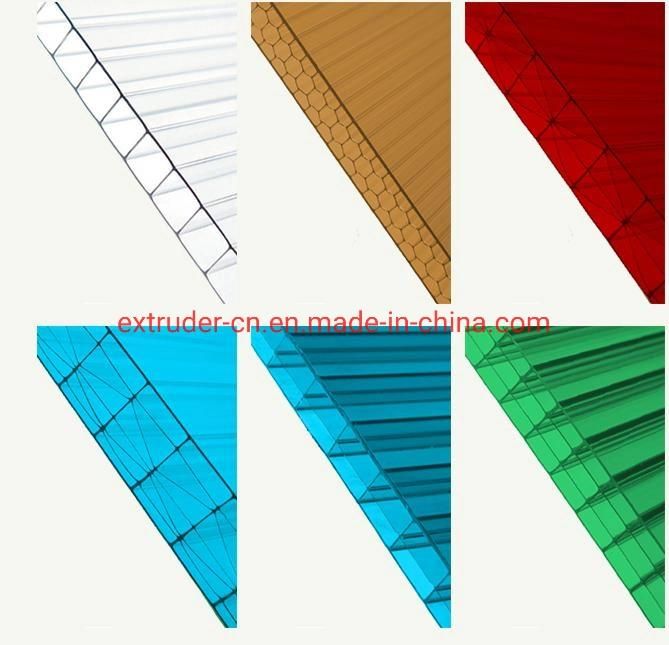

samples pictures:

Packaging & Shipping

All the machines will be packed with wooden pallets/cases with wrapping films or other sea-worthy packing method, by sea, by train or by air.

Trade shows :

Company certifications: