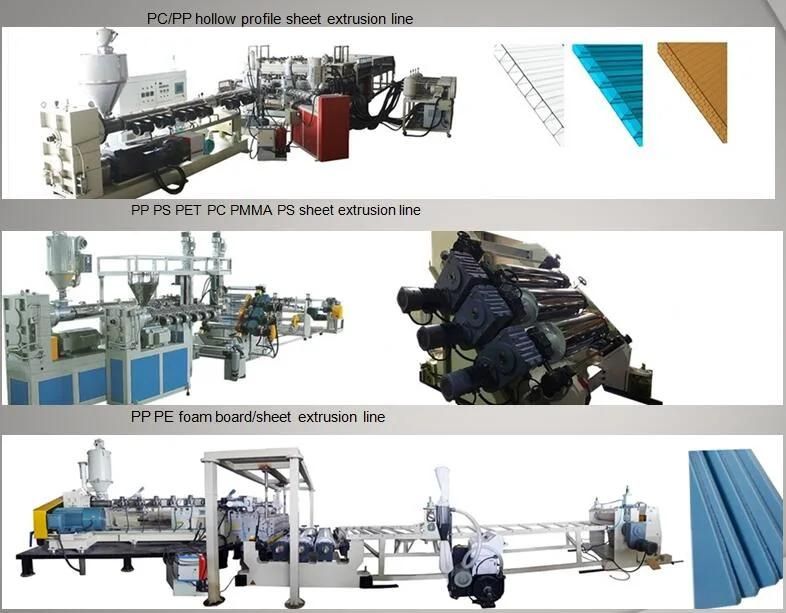

HIPS Sheet Extrusion Line Machine for Thermoforming

Qingdao Leader Machinery Co., Ltd.- Product Type:PS Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

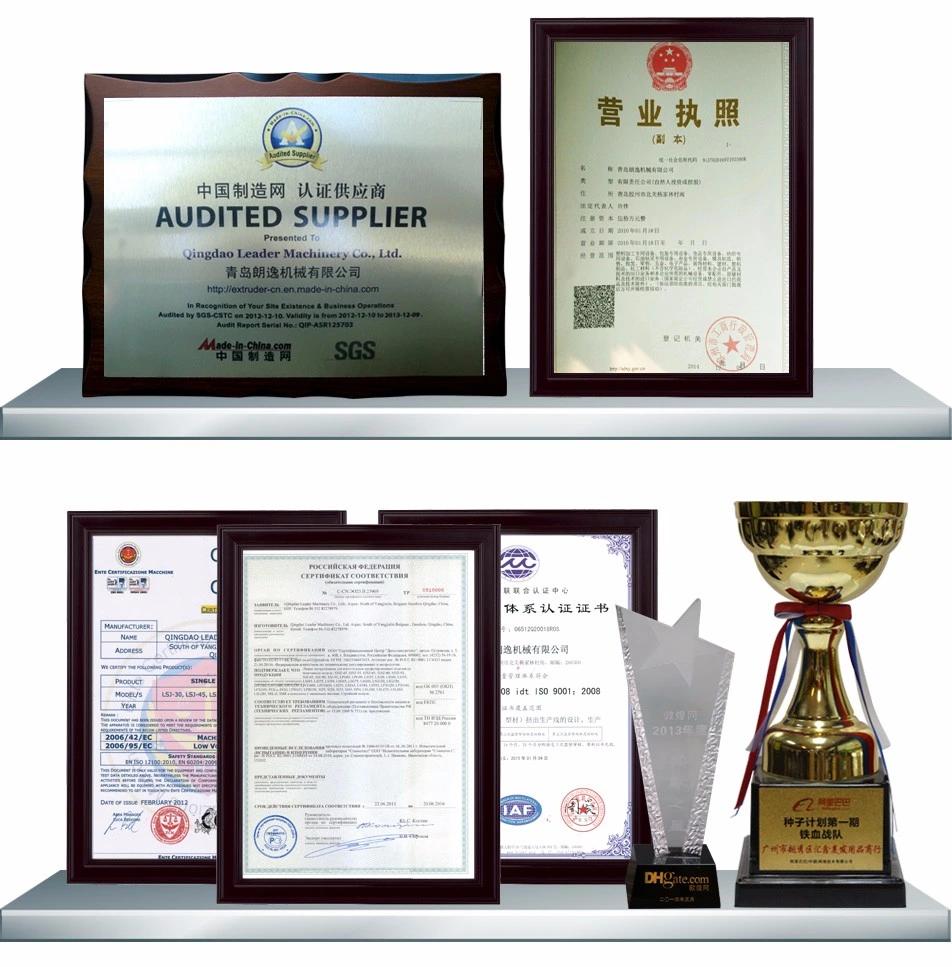

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:LSJ-90,33

- Customized:Customized

- Condition:New

- Sheet Width:600-1200mm

- Sheet Thickness:0.2-2mm

- Raw Material:HIPS, PP, EVOH, EVA etc

- Extruder Model:Sj90,33

- T-Type Die Head:Jc-Times Brand

- Main Electrical Parts:ABB, Omron, Rkc, Schneider, FUJI, Delix etc.

- Delivery Time:60 Days

- Guaranteed Time:12 Months

- Quality Control:Customer Come to Our Factory to Check

- Transport Package:Wooden Case or Other Moistureproof Packages

- Specification:SJ-90,33

- Trademark:Leader Machinery

- Origin:Qingdao of China

- HS Code:84772090

- Production Capacity:20 Sets,Year

Description

2. Can be recyclable material, like PET Bottle Flakes

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 9 CONTACT INFORMATION: