PLA/Pbat/Corn Starch+Polymer Bioplastic Twin Screw Extruder

Nanjing Kairong Machinery Tech. Co., Ltd.- After-sales Service:Online Service

- Warranty:1 Year

- Raw Material:LDPE HDPE PE PP Pet PA6 PC ABS PVC

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

Base Info

- Model NO.:TSE-50

- Automation:Automatic

- Computerized:Computerized

- Customized:Customized

- Certification:CE

- Condition:New

- Keyword:Plastic Extruder Machine

- Place of Origin:Jiangsu, China

- Application:Compounding, Cutting, Pelletizing, Granulating

- Extruder:Parallel Twin Screw Extruder

- Diameter of Screw:62.4mm

- Motor:Wannan or Siemems

- Power:90 Kw

- Capacity:200-300 Kg,H

- Screen Changer:Hydrulic Screw Changer

- Comtroller:PLC

- Transport Package:Export Wood Packing with Soft Plastic Foam

- Specification:CE ISO9001 SGS

- Trademark:kaironggroup

- Origin:Nanjing Jiangsu

- HS Code:84772090

- Production Capacity:200-300kg,H

Description

Basic Info.

Model NO. TSE-50 Automation Automatic Computerized Computerized Customized Customized Certification CE Condition New Keyword Plastic Extruder Machine Place of Origin Jiangsu, China Application Compounding, Cutting, Pelletizing, Granulating Extruder Parallel Twin Screw Extruder Diameter of Screw 62.4mm Motor Wannan or Siemems Power 90 Kw Capacity 200-300 Kg/H Screen Changer Hydrulic Screw Changer Comtroller PLC Transport Package Export Wood Packing with Soft Plastic Foam Specification CE ISO9001 SGS Trademark kaironggroup Origin Nanjing Jiangsu HS Code 84772090 Production Capacity 200-300kg/HProduct Description

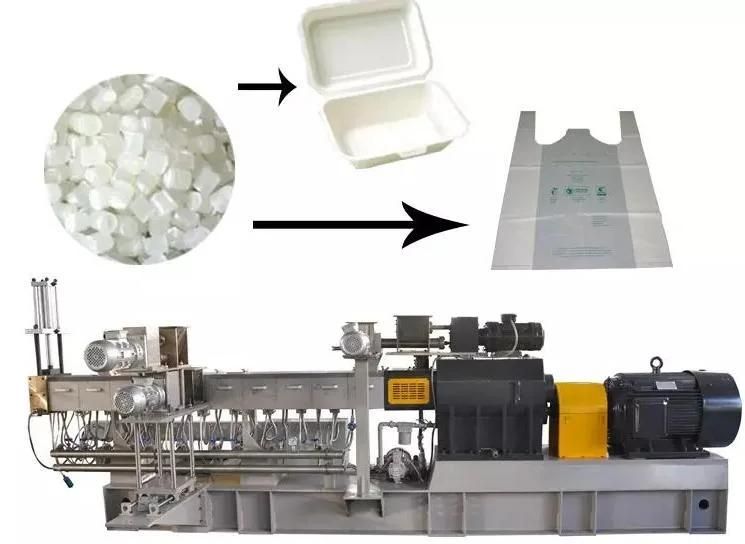

Bio plastic machine

Biodegradable plastic is an irresistible trend.

Haisi Extrution is specialist for complete bio plastic machine. We can provide entire plant for bio plastics extrusion & compounding.

Starch and pp pe ps are degradable after mixing,and it is mainly used as agricultural film and horticultural material in agriculture; the application in catering industry is mainly used as fast food boxes, disposable cups, plates, and knives and forks; the packaging materials are mainly the packaging of daily items, including various shopping bags, Bags, garbage bags, food bags, etc.

Technical data of bio plastic machine

Technical data of bio plastic machine| Mode | Diameter (mm) | L/D | speed (r/min) | Motor power (kw) | Torque (N.m) | Capacity (kg/h) |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

| TSH-65B | 62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-500 |

| TSH-75B | 71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

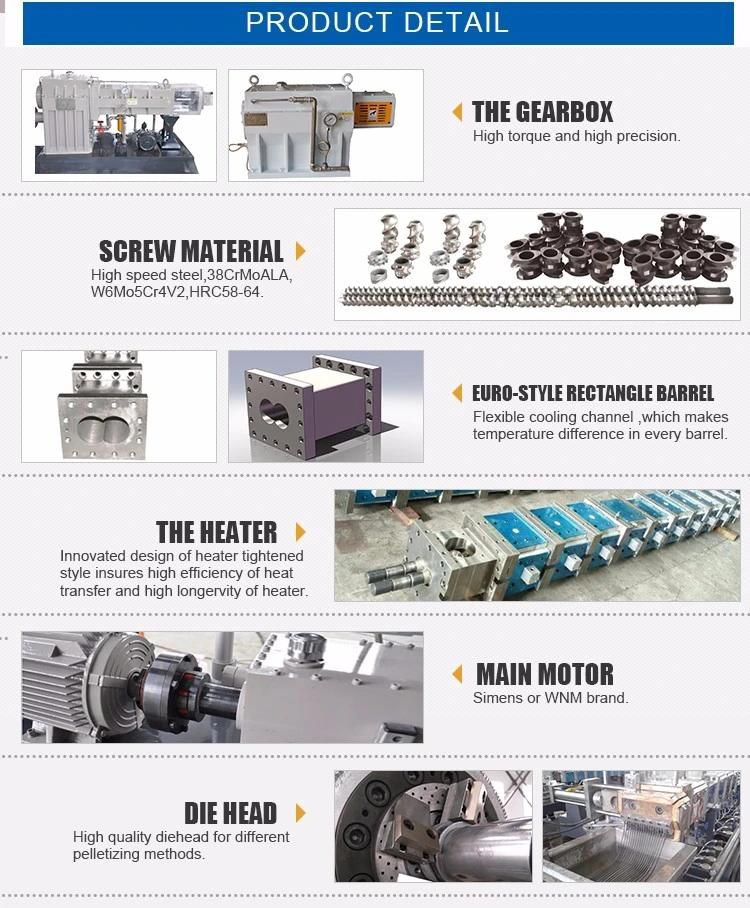

Product Description of bio plastic machine

1) Biodegradable Additive Masterbatch

When plastic becomes waste, its durability becomes a problem - it takes plastics 500 to 1000 years to naturally degrade.

Compound the Degradable Additive Masterbatch with any plastic such as PE/PET/PP etc. It speeds up the molecular and chemical degradation of plastic, thus helping to solve the massive accumulation of plastic waste.

Extruding & pelletizing flow scheme of bio plastic machine

1.Water cooling strand pelletizing line for bio plastic machine <PBAT+TPS compounding>

2.Water Ring Extruders for bio plastic machine<PLA+starch,PBAT+stacrc,etc.>

3.Air-cooling hot cutting line for bio plastic machine< PE,PS etc.+starch,additive etc.>

4. Underwater pelletizing for bio plastic machine

Characteristics of bio plastic machine

*Our bio plastic machine use innovated design of heater tightened style, it insures high efficiency of heat transfer and high longevity of heater.

*Our plastic extrusion machine has Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing etc.

*The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistant and high functions

*The screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.