Plastic Home-Use Products Inject/Injection Mould/Molding Machine/Machinery 280ton

Taizhou Doria Plastic Equipments Co., Ltd.- Type:Preform Injection

- Structure:Horizontal

- Plastic Type:Thermoplastic

- Plasticizing Way:Screw Type

- Clamping Way:Hydraulic & Mechanical

- Automation:Automatic

Base Info

- Model NO.:injection machine 280

- Computerized:Computerized

- Certification:CE

- Product Capacity:280ton

- Injection Weight:270g

- Motor:Servo

- Payment:T,T;LC

- Delivery:35-45days

- Application:Commodity

- Transport Package:Plastic Film

- Specification:metal

- Trademark:D-R

- Origin:Taizhouhuangyan

- HS Code:8477101090

- Production Capacity:Clamping Stroke 50tons

Description

Basic Info.

Model NO. injection machine 280 Computerized Computerized Certification CE Product Capacity 280ton Injection Weight 270g Motor Servo Payment T/T;LC Delivery 35-45days Application Commodity Transport Package Plastic Film Specification metal Trademark D-R Origin Taizhouhuangyan HS Code 8477101090 Production Capacity Clamping Stroke 50tonsProduct Description

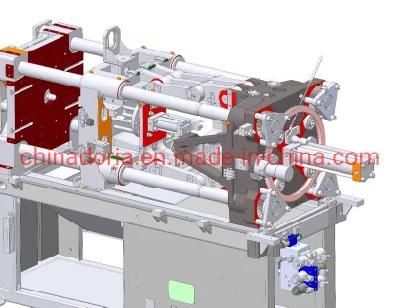

Specification of D-RI280 plastic injection moulding machine1. Product details:

2. Technical data of D-RI280

| Type items | D-RI 280 |

| Screw diameter (mm) | 65 |

| Injection pressure (Mpa) | 155 |

| Shot weight(PS) | 890 |

| Screw L/D ratio (L/D) | 18:4:1 |

| Screw stroke(mm) | 322 |

| Screw speed (r.p.m) | 0-160 |

| Injection rate (g/s) | 270 |

| Plasticizing capacity | 40 |

| Clamping force (KN) | 280 |

| Mould clamping stroke (mm) | 550 |

| Max daylight opening (mm) | 1170 |

| Mould thickness(Min-Max) | 230-620 |

| Space between Tie-bars (mm) | 580*580 |

| Hydraulic ejection force(tons) | 7.0 |

| Hydraulic Ejector stroke (mm) | 145 |

| System pressure | 16 |

| Pump motor power (KW) | 22 |

| Heat power (KW) | 14 |

| Temperature control zones | 4+1 |

| Tank capacity(L) | 500 |

| Machine dimension (m) | 5.8*1.65*2.05 |

| Machine weight (ton) | 11 |

3. Specifications

Injection molding machine

3.1.Big tie bar space and shot weight capacity

3.2.Most famous component parts

3.3.Perfect after-service

4. HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two-way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

5. Worshop of machine:

6. Warehouse of machine:

8. Frequently Asked Questions:

8. Frequently Asked Questions:Q: Where is your loading port?

A: Ningbo/Shanghai, China or else port as for your request.

Q: Where is your company?

We are located in Taizhou city Zhejiang Province, very convenient for shipping.

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or inform us by email, so that we will regard your inquiry in priority.

Q: Can you make bottle designs to us?

A: Yes. We have a professional team having rich experience on products designs. You could send bottle samples to us, and we could make designs according to the samples. Or you could send us the sketch of design, and we could make detail 3D designs to you to check.

Q: What is your selection of shipping method?

A: (1). For small trial order, international express, just as TNT, DHL, FedEx, UPS, EMS is suitable.

(2). For large order, we can arrange shipment by sea or air according to your requirement.

9. About us:

Automatic blowing bottle mould manufacturer:

One cavity automatic Blowing Bottle Mould for 5L oil bottle

2 Cavity Automatic Blowing Bottle Mould up to 2L

3cavity Automatic Blowing Bottle Mould

4cavity Automatic Blowing Bottle Mould

6 Cavity Automatic Blowing Bottle Mould up to 1L

Taizhou Doria Plastic Equipment Co., Ltd. is located the town of plastic products and mould in China, which is one manufacturer owns special production teams, advanced production equipments and rich production experience.

We have good market in South America, Africa, Asia, Europe, North America, and our many customers from Canada, Brazil, Thailand, Chile, Algeria etc.

Meanwhile, the output of our main product automatic 5gallon blow moulding machine could achieve 600pcs/h which is the breakthrough of our company.

Welcome everyone to visit us, we hope we will have good chance to cooperate!

10. Location:

No.362 Lingxiage Village

Xicheng Street, Huangyan

Taizhou, Zhejiang

China

11. Contact us: