Plastic Clothes/Coat Hanger Inject/Injection Mould/Molding Machine 120ton

Taizhou Doria Plastic Equipments Co., Ltd.- Type:Preform Injection

- Structure:Horizontal

- Plastic Type:Thermoplastic

- Plasticizing Way:Screw Type

- Clamping Way:Hydraulic & Mechanical

- Automation:Automatic

Base Info

- Model NO.:injection machine 120

- Computerized:Computerized

- Certification:CE

- Product Capacity:120ton

- Injection Weight:183G

- Motor:Servo

- Payment:T,T;LC

- Delivery:35-45days

- Application:Commodity

- Transport Package:Plastic Film

- Specification:metal

- Trademark:D-R

- Origin:Taizhouhuangyan

- HS Code:8477101090

- Production Capacity:Clamping Stroke 120tons

Description

Basic Info.

Model NO. injection machine 120 Computerized Computerized Certification CE Product Capacity 120ton Injection Weight 183G Motor Servo Payment T/T;LC Delivery 35-45days Application Commodity Transport Package Plastic Film Specification metal Trademark D-R Origin Taizhouhuangyan HS Code 8477101090 Production Capacity Clamping Stroke 120tonsProduct Description

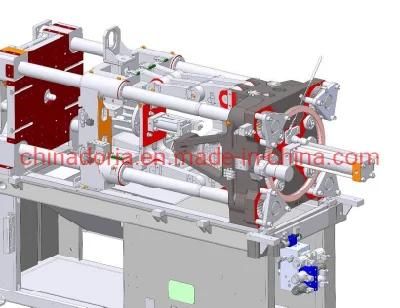

Specification of plastic hanger injection moulding machine D-RI1201. Product details:

2. Technical data of D-RI120

| Model Item | D-RI120 |

| Screw diameter(mm) | 40 |

| Injection pressure(Mpa) | 170 |

| Shot weight(PS) (g) | 183 |

| Screw L/D ratio | 20:1 |

| Screw stroke (mm) | 170 |

| Screw speed(r.p.m) | 10-170 |

| Injection rate (cm3/s) | 122 |

| Plasticizing capacity(g/s) | 20.1 |

| Clamping stroke(tons) | 120 |

| Mould clamping stroke (mm) | 375 |

| Max. daylight opening (mm) | 775 |

| Mould thickness (Min.-Max.) (mm) | 150-400 |

| Space between tie-bars (mm) | 375*415 |

| Hydraulic ejection force (tons) | 3.8 |

| Hydraulic ejector stroke (mm) | 110 |

| Max. pump pressure(Mpa) | 16 |

| Motor power(KW) | 13 |

| Heater power(KW) | 6.3 |

| Temperature control zones | 3+1 |

| Tank capacity (L) | 220 |

| Machine dimension(L*W*H) | 3940mm*1280mm*1795mm |

| Machine weight(ton) | 4.2 |

We are the leading trader of New Plastic Injection Moulding Machine 120Ton. This product is produced with the use of high-grade raw material with advanced techno machinery under the guidance of experienced engineers, keeping in mind its application area. It is provided with suction line and return line filtration. These products are highly demanded by our clients in market for their silent features.

Features:

Noise-free machine operation

Long operational life

Low maintenance

3. Technical and after-sales service:

The supplier the following technical and after-sales service commitment

A) Provide on-site installation guide;

B) Responsible for the commissioning of equipment;

C) Responsible for the buyer's personnel mount guard before the operation and maintenance training;

D) one year free warranty (due to the buyer's improper operation caused by damage charge costs), and ensure the supply of spare parts for a long time, only receive the cost.

E) Provide technical advisory services for a long time

4. Delivery date: the contract is signed and completed within 45 working days after receiving the deposit unit processing and manufacturing, with the conditions of the factory acceptance

5. worshop of machine:

6. Warehouse of machine:

8. Frequently Asked Questions:

8. Frequently Asked Questions:Q: What are your company's main products?

A: The main products of our company are following: Automatic & semi-automatic blow moulding machine, PET preform, plastic injection machine, preform moulds, bottle moulds, commodity moulds and correlative products.

Q: What is your selection of shipping method?

A: (1). For small trial order, international express, just as TNT, DHL, FedEx, UPS, EMS is suitable.

(2). For large order, we can arrange shipment by sea or air according to your requirement.

Q: How do you control the quality?

A: We do 3times leakage test before packing.

Q: Which trade terms do you prefer?

A: We can accept FOB, CIF, CFR, etc.

9. About us:

Taizhou Doria Plastic Equipment Co., Ltd. is located the town of plastic products and mould in China, which is one manufacturer owns special production teams, advanced production equipments and rich production experience.

Based on "Quality is first; Honor for the honest", we always continue development and innovation to witness the maturity of industrial chain of products and improve the quality of products continually. Untiring effort makes the products, especially for 5gallon blow moulding machine, 5gallon PET preform and commodity moulds are widely accepted by our customers.

10. Location:

No.362 Lingxiage Village

Xicheng Street, Huangyan

Taizhou, Zhejiang

China

11. Contact us: