PVC WPC Wood Plastic Composite Celuka Foam Board Furniture Cabinet Sheet Making Machine

Qingdao Tongsan Plastic Machinery Co., Ltd.- After-sales Service:Engineer Oversea Service

- Warranty:12 Month

- Type:WPC Door Extrusion Line

- Plastic Processed:WPC

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:SJSZ-80,156

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Main Motor Power:75kw,90kw,110kw

- Motor Brand:Siemens

- Inventer:ABB

- Contactor:Schneider

- Temperature Controller:Omron

- Transport Package:Sea Worth Package

- Specification:SJMS80,156, SJMS80,173, SJMS92,188

- Trademark:HEGU

- Origin:China

- HS Code:84772090

- Production Capacity:50 Sets One Year

Description

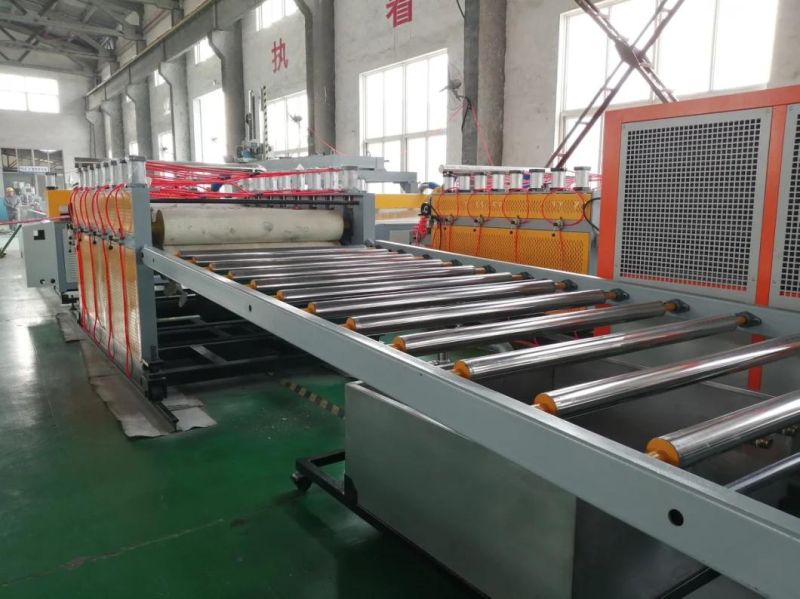

Main technique parameter:

| Items | Machine | Quantity | Notes |

| 1.1 | SJMS80/173 Conical double screw extruder | 1 set | With auto feeder |

| 1.2 | Mold and calibrators for 1220mm width , and 18-35mm thickness | 1 set | With 5 lips |

| 1.3 | WPC board calibrating device | 1 set | 5 calibrators |

| 1.4 | Cooling bracket, it can equip online embossing and online hot transferring or laminating machine. | 1 set | 5 meters length |

| 1.5 | Protection film coating device | 1 set | Double face type |

| 1.6 | Haul-off machine | 1 set | 10 groups of rollers |

| 1.7 | Width(Edge) cutting machine | 1 set | Two sides cutting |

| 1.8 | Length Cutting machine | 1 set | Fixed length auto cutting |

| 1.9 | Dust suction machine | 1 set | collecting cutting dust |

| 1.10 | Product stacker | 1 set | 3 meters |

| 1.11 | Siemens PLC Electric control system | 1 set | High quality world famous |

(1)Twin conical screw extruder

According to different thickness of products, equip different model extruder

Siemens motor

ABB inverter

Omron temperature controller

(2)T-die mould

China famous brand mould,which special for foam board

(3)Calibrator

(4)Cooling frame

the cooling stacker is used for cooling the WPC foam board to ensure the flatness of the board.

(5)Hual off machine

WPC foam board requires very strong haul off force,so that we equip 8-10 pairs rubber rollers for haul off.

(6)Cutting machine

WPC foam board automatic length cutting machine

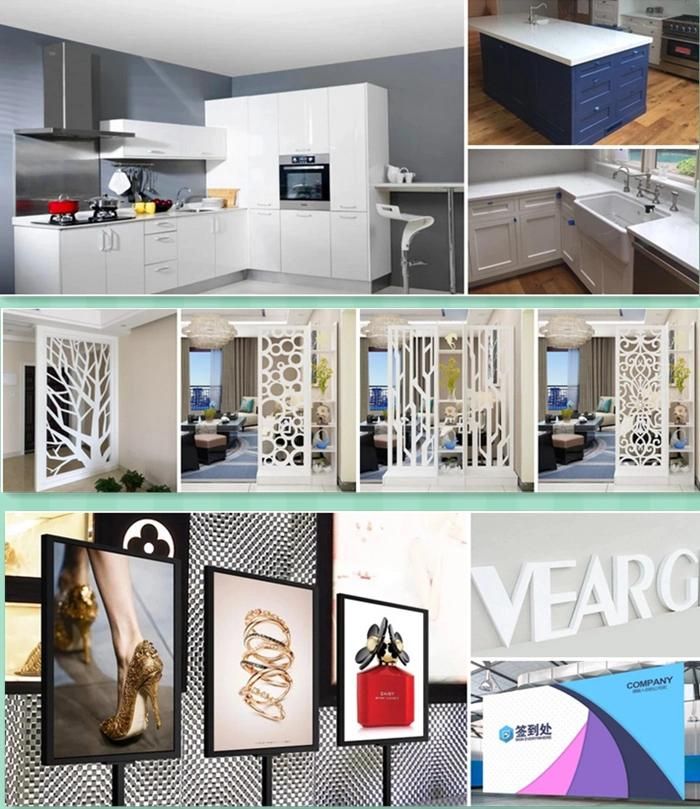

Application for PVC WPC FOAM BOARD

Application for PVC WPC FOAM BOARD1)Advertising field: sign board, billboard, exhibition display, silk screen printing, laser engraving material

2) Building and upholstering: models, partitions, wall cladding, construction wall indoor or outdoor decoration,false ceilings, office furniture, kitchen and bath cabinet

3) Industrial use: chemical industry antiseptic project, heat moulding, refrigerator sheet,special freezing project, environmental friendly engineering.

4) Traffic and transit: internal decoration of ship, plane, bus, train, roof wing-room or others, compartment core layers.