FB-B-800 HDPE/LDPE Film Blowing Machine Po Blown Film Machine

Ruian Hoin Machinery Co., Ltd.- After-sales Service:Technical Support Online

- Warranty:One Year

- Type:PE Film Blowing Machine

- Raw Material:PE

- Maximum Folding Width of Film:800mm

- Screw Diameter:55mm

Base Info

- Model NO.:FB-B-800

- Automation:Automatic

- Computerized:Computerized

- Machine Weight:3600kgs

- Certification:CE, ISO9001:2008

- Suitable Material:LDPE,HDPE,LLDPE

- Output:50kg,H

- Die Size:80 and 160mm

- Transport Package:Wooden Package

- Specification:4600*2200*4400

- Trademark:HOIN

- Origin:Ruian, Zhejiang, China

- HS Code:8477309000

- Production Capacity:30 Sets,One Month

Description

Basic Info.

Model NO. FB-B-800 Automation Automatic Computerized Computerized Machine Weight 3600kgs Certification CE, ISO9001:2008 Suitable Material LDPE/HDPE/LLDPE Output 50kg/H Die Size 80 and 160mm Transport Package Wooden Package Specification 4600*2200*4400 Trademark HOIN Origin Ruian, Zhejiang, China HS Code 8477309000 Production Capacity 30 Sets/One MonthProduct Description

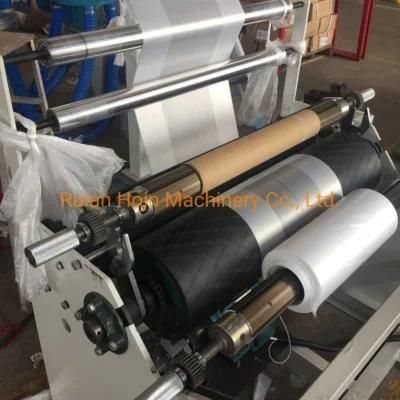

FB-B-800 PE Film Blowing Machine

1.Main technical variables:

| Model | FB-B-800 |

| Screw Diameter | 55MM |

| Screw Ratio | L/D28:1 |

| Screw Speed | 10-100r/min |

| Power of Main Motor | 15KW |

| Power of traction main motor | 1.5kw |

| Main Output | 50kg/h |

| Max.Folding Width of Film | 200-800mm |

| Single-sided Thickness of Film | 0.008-0.10mm |

| Overall Dimensions | 4600x2200x4400mm |

Suitable Material: HDPE/LDPE/LLDPE

Max.Folding Width of Film (mm): 800

Thickness of Film (mm): 0.008-0.10MM

Max. Output (Kg/Hr.): 50kg/h

Extruder

Screw Dia. (mm): φ 55

Screw & Barrel L/D Ratio: 28: 1

Screw & Barrel material: 38 CRMOALA

Barrel Auto Thermo Control: 3 Points

Cooling Blower : 1.5kw

Gear box: water cooling reducer, hard tooth surface use 1473# type

Driving Motor: 15kw

Screen Changer: manual type

Screen Changer Heater Capacity (Kw): 1.5

Die:

Die Dia. (mm): 80mm and 160mm

Die Heater Capacity (Kw): 3

Die Auto Thermo Control: 1 Points

Air Ring: 1 Set per Die

Bubble Basket: Hexagon Type

Folding devices ( from the double sides ) ,

max.folding : The 10cm

Take-up Unit:

To be possible to moving the tower 1.5m

Pinch Roller- Embrorosing Roller

Take-up Motor with Inverter Control: AC 1.5kw

Winding Unit

Max. Width (mm): 800

Max. Wind-up roll dia. (mm): φ 800

Winding Motor: 10Kg/Nm with moment motor

Rewinding Speed: 5-50m/min

3.Spare Part List:

| 01 | filter | 1 M | 08 | electric -testing pen | 1 pcs |

| 02 | magetic stone | 1 pcs | 09 | hexageonic wrench | 1 pcs |

| 03 | air pipe | 1 pcs | 10 | glove | 2 pairs |

| 04 | 8-10 open and wrench | 1 pcs | 11 | Steady Bar | 1 pcs |

| 05 | 12-14 open and wrench | 1 pcs | 12 | Mould Pipe | 1 pcs |

| 06 | 14-17 open and wrench | 1 pcs | 13 | electric-thermal couple (E) | 2 pcs |

| 07 | 17-19open and wrench | 1 pcs | 14 | screw heater(stainless steel) | 1 pcs |

5. Workshop of HOIN

5. Workshop of HOIN

6. More Products Optional:

6. More Products Optional: 7.After Service of HOIN:

7.After Service of HOIN:1. How long will your engineer reach to our factory?

Within one week after machine arrival at your factory.

2. How many days will you finish installing?

We will finish installation and training within 15days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets, hotel, food, and also their salary 100USD per day per person.

4. How long of your machine's warranty period?

Our machines have one year guarantee after finishing installation.

5. How could we do after one year warranty period?

We will still offer you our best after service, and need you to afford our technician's cost.

6. Can you find us any engineer in our location?

Of course, we will check and inform you as soon as possible.

Any query please feel freely to contact with us!

MS.WendyPan