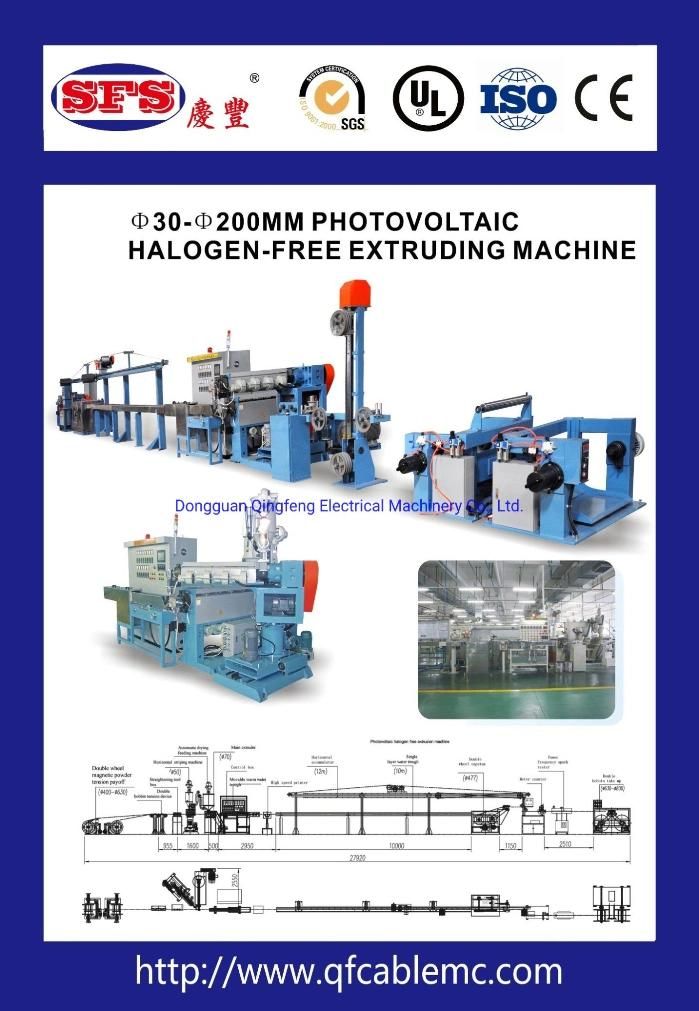

Qf-120 Photovoltaic, No Halogen Extruding Production Line for Wire and Cable

Dongguan Qingfeng Electrical Machinery Co., Ltd.- Type:Pipe Extruder

- Plastic Processed:PVC, PE, PP, PU, Nylon and So on

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

- Assembly Structure:Separate Type Extruder

- Screw:Multi-Screw

Base Info

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Warranty Period:12 Months

- Heating System:Electric

- Customized:Customized

- Precision:Precision

- Voltage:380V

- Brand:Sfs

- Power:3p 380V 50Hz

- PLC Brand:Siemens

- Usage:Extruding

- Inverter Brand:Yaskawa

- Transport Package:Shipment or Wooden Box (Required by Yours)

- Specification:CE, SGS, RoHS

- Trademark:SFS

- Origin:Dongguan, Guangdong Provice

- Production Capacity:40

Description

Basic Info.

Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Warranty Period 12 Months Heating System Electric Customized Customized Precision Precision Voltage 380V Brand Sfs Power 3p 380V 50Hz PLC Brand Siemens Usage Extruding Inverter Brand Yaskawa Transport Package Shipment or Wooden Box (Required by Yours) Specification CE, SGS, RoHS Trademark SFS Origin Dongguan, Guangdong Provice Production Capacity 40Product Description

It's suitable for various kinds of low smoke, no halogen electronic wires, computer wires, construction wires and data communication wires.The most basic machines list of production line

Pay-off stand

Tension stand

Copper preheater

Main extruder

Main electrial control box

Laser diameter tester

Accumulator

Capstan machine

Speak tester

Meter counter

Take-off machine

Product application

1. This production line adopts PLC controller, professional industrial control software, industrial computer and strorage display.

2. The machine adopts the extrusion of material s of halogen or PVC, PE, PU, Nylone, etc. by changing different types of screw

3. This production line adopts precise automatic detecting feedback system which can guarantee the production speed, control sensitivity precision and reduce the errors of the diameter.

4. Applied to advanced testing instrument and strict detecting system to ensure every part of extrusion line linked freely and smoothly

Technological parameters

1. Cylinder dia. : Φ120mm.

2. L/D : 25:1.

3. Screw rotate speed(max.) : 70RPM.

4. Extruded capacity : 300kg/hr.

5. Suitable extruded wire dia. : Φ8.0 - 60.0mm.

6. Wire speed(max.) : 150m/min.

7. Motor of pay-off stand : 1000mm rainbow motor driven.

8. Pre-heater : 5KVA high frequency induction.

9. Motor of extruder : 132KW 4P AC motor.

10. The capacity of auto-feeding : 150kg.

11. The dia. control range : ±0.01mm.

12. Tempurature control range : ±1°C.

13. Cooling water sink : "U" shape single layer.

14. The retractor dia. : Φ636 double wheels.

15. Motor of traction : 5.5KW 4P AC motor.

16. The max. store wire length : 250m.

17. Motor of take-up : 5.5KW 4P AC motor.

18. Bobbin dia. of take-up : Φ600mm-Φ1600mm

International market

USA, Italy, Korea, Vietnam, Thailand, Indonesia, Turkey, Iraq, Japan etc.

Cooperative partner

America Tyco and Belden, Madison, Japanese Mitsubishi etc.

About us

Qingfeng electrical machinery factory was found in 2000. It is located in Dongguan city, China. It is an enterprise which devotes to equipment technology research and design and manufacturing. Mainly engaged in various wire, cable and optical cable equipment research, development and bulk production. We mainly manufacture various extruding lines, twisting machines and other peripheral equipments such as physical and chemical foaming extruding production lines, cage-type twisting machine, high speed double twisting machine, back twisting machine and coiling machine and so no.

Customer service

1. We provide installation knowledge, machine testing knowlege and training operator freely.

2. We track maintenance service regularly for solving the problems in practice.

3. We provide the spare parts and technical support for our customer all the time.

Main parts brand

- Motor: Siemens

- Frequency converter: Yaskawa or Invoance

- Bearing: NSK (Japan brand)

- Electrical component: Siemens or Omron

- PLC controller: Siemens

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Customized design support.

* View our Factory.

After-Sales Service

* Training how to install and how to use the machine

* Engineers available to service machinery overseas.

Safety performances:

1) Switch-off at overpressure

2) Disabling signal at under temperatures

3) Stop at over temperature

3) Motor power limit

4) Emergency stop

5) Monitoring of tolerances and alarms

6) Monitoring of sensors

Machine picture:

Qingfeng Electrical Machinery is a high-tech enterprise dedicated to the r&d, manufacturing and service of high-frequency wire and cable, optical cable and other equipment technology..We can according to the customer's special requirement to provide the ideal solution, based on the cable structure, combine with the actual technical requirement, and to provide the professional corresponding technical solution.

About us

Dongguan NewTopp Electrical Machinery Co.,Ltd is a high-tech enterprise which specializes in developing and manufacturing wire and cable machines, and our main products includes all kind of extrusion production line, single twisting machine, double twisting machine, cantilever stranding machine, cage-type twisting machine, planetary cabling machine, triple-core stranding with back-twist and taping, and single layer/double layer taping machine etc. and our products have passed CE certification and SGS audited , and we also have passed ISO9001:2008 since 2010.

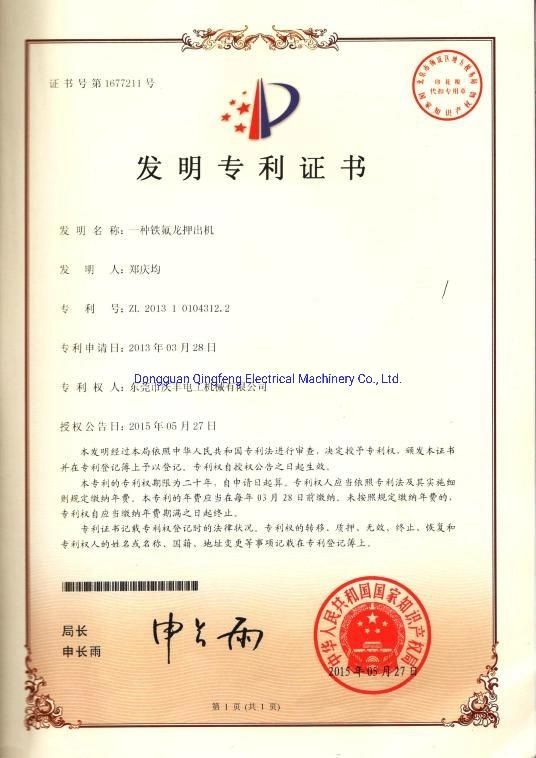

Certification and Patent

Packaging & Shipping

1) Transparent PE film + Wooden box

2) Cardboard wrapping corner to protection, fixed with steel wirerope in the container.

FAQ

− Q: Are you the manufacturer or trading company?

A: We are a manufacturer with more than 10 years manufacturing exprience in cable machinery, and we have9000 spuare meters production workshop and office space.

− Q: What is your company's main production?

A: We specialized in optical fiber and optical cable machine researching and manufacturing. Our products include Optical fiber coloring and rewinding machine series, Optical fiber secondary coating line series, Optical cable stranding line, Optical fiber cable sheathing line series and other optical cable equipment.

− Q: What can we offer our customers?

A: Our professional production and technical personnel can train our customers' employees and ensure the smooth production of customers. And will provide our customers with after-sales service.

− Q: How long is the machine warranty?

A: Warranty period of one year (since the completion of mechanical debugging at the buyer's factory)

− Q: Why do I choose your company?

A: We have more than 20 years of professional experience in the production of cable machinery, providing high-quality, high-security products.

We have an experienced team of skilled workers and engineers.

We can support overseas training engineers.

We can customize the design, to accept the customer's sample design.

We can provide customers with after-sales service.

− Q: How can we get to your factory to see the machines works?

Address: Cunzheng road,Renzhou Village ,Shatian Town, Dongguan City,Guangdong Province,China

We are near to Shenzhen Baoan International airport within 40 mins;

We are close to Guangzhou Baiyun Airport for 1.5-2 hours;

High speed rail from Guangzhou south station to Humen station.