Agriculture Waste Plastic Film Flakes Washing Recycling Machinery Line

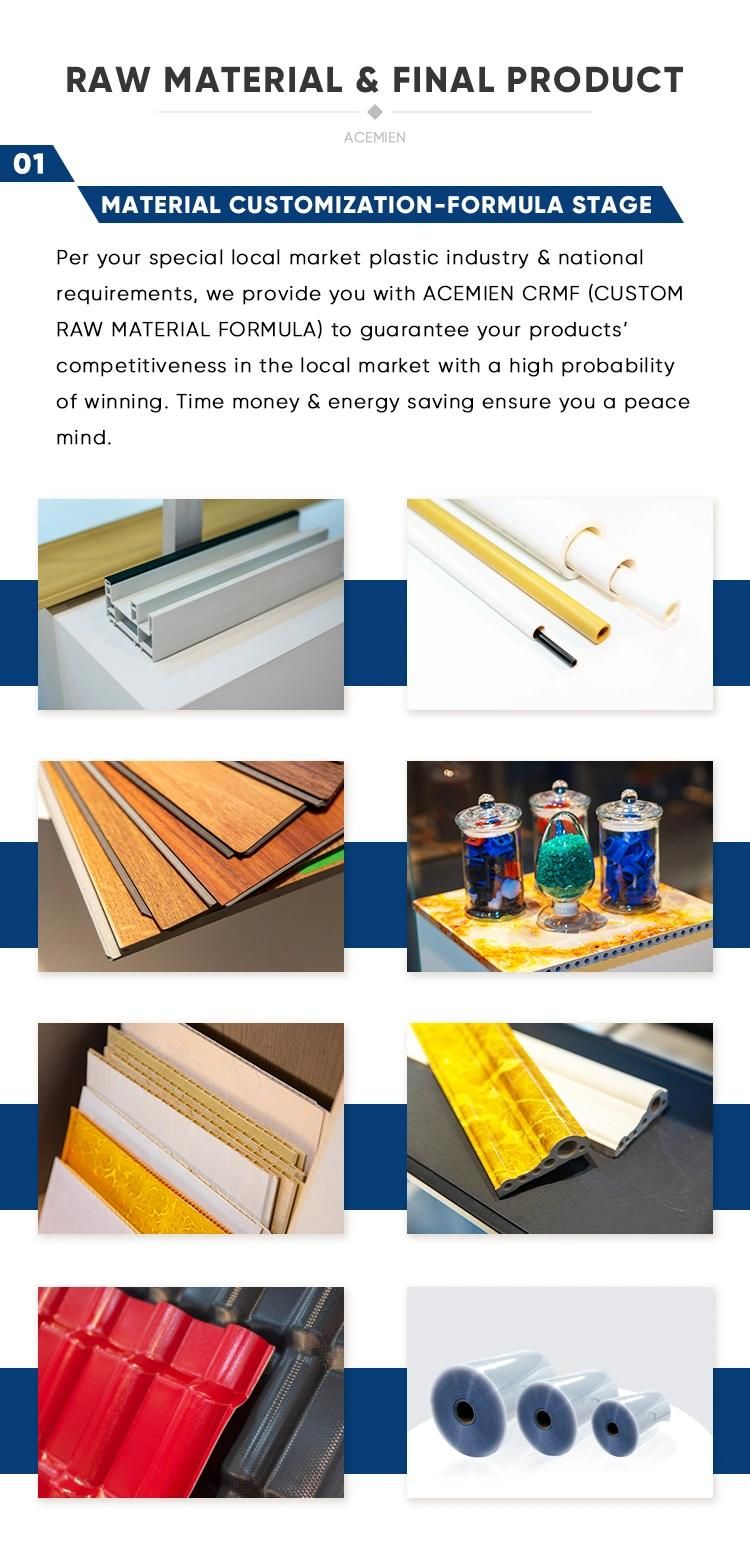

Jiangsu Acemien Machinery Co., Ltd.- Material Processed:Bottle,Film,Bag,Pipe etc

- Plastic Type:PE PP HDPE LDPE Pet BOPP etc

- Screw:Double-Screw

- Automation:Automation

- Computerized:Computerized

- Certification:CE

Base Info

- Model NO.:PE-001

- Output:300-2500 Kg,H

- Guarantee Period:12 Months

- Delivery Time:30-90 Workdays

- Transport Package:Wooden Case ,Plastic Film(or Customer′s)

- Specification:PE 300-2500

- Trademark:ACEMIEN

- Origin:China

- HS Code:84778000

- Production Capacity:350 Sets,Year

Description

Total10 sets All brands can accoring customer's requirements.

We can design a complete films washing line according to your request.

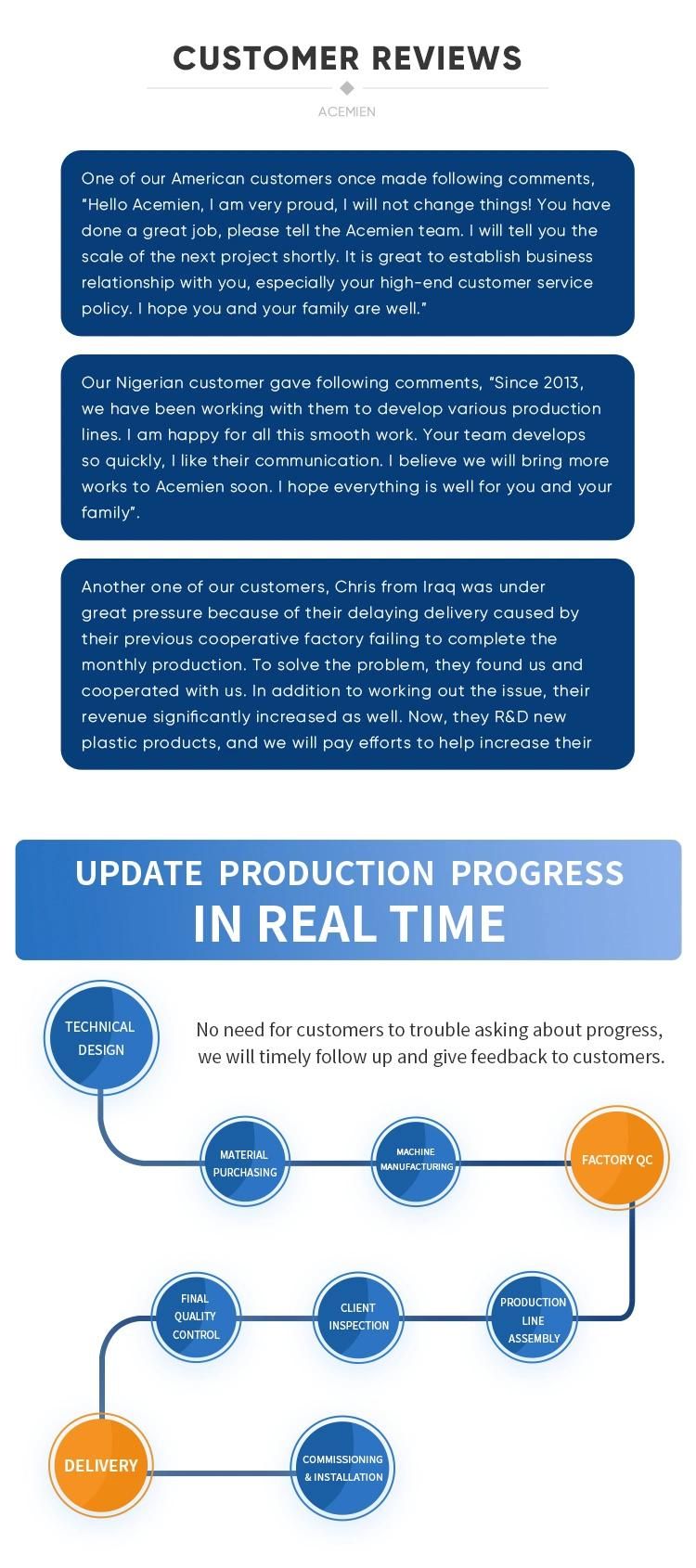

1. Belt conveyor: Convey material to next process.

2. Crusher: Crush the materials to flakes of 15mm (two series: one for PET, one for PP/PE)

3. Friction washer: Surface clean the materials (two series: one for PET, one for PP/PE), and transport material to next washing equipment.

4.Hot washer:Add cleaner to hot water,can clean the oil,sand,soil,glue etc.Two kinds heating types,steam or electrical heating,customer can choose one or both.Electric heating motor 60kw.

5. Float Washer: For separation of the flakes with a specific density of <1g/cm^3 from >1g/cm^3 or in contrast to separate the flakes with a specific of > 1g/cm^3 form <1g/cm^3 (PET >1g/cm^3 and PP/PE <1g/cm^3)

6. Screw feeder: transport material and as well as for rub them for surface cleaning.

7. Dewater machine: for mechanical surface drying of the material flakes with rotating roller (two series: one for PET, one for PP/PE)

8. Pipe dry system: Using stainless steel "U" type pipeline and cyclone silo to dry the material to the necessary residual level for downstream material processing.

9.Silo: Storage for final products.

General information(Take capacity 500kg/h Waste Film Recycling Production Line as example):

Work condition (provide by customer):

Energy consumption:

Main commercial terms:

We can design a complete films washing line according to your request.

1. Belt conveyor: Convey material to next process.

2. Crusher: Crush the materials to flakes of 15mm (two series: one for PET, one for PP/PE)

3. Friction washer: Surface clean the materials (two series: one for PET, one for PP/PE), and transport material to next washing equipment.

4.Hot washer:Add cleaner to hot water,can clean the oil,sand,soil,glue etc.Two kinds heating types,steam or electrical heating,customer can choose one or both.Electric heating motor 60kw.

5. Float Washer: For separation of the flakes with a specific density of <1g/cm^3 from >1g/cm^3 or in contrast to separate the flakes with a specific of > 1g/cm^3 form <1g/cm^3 (PET >1g/cm^3 and PP/PE <1g/cm^3)

6. Screw feeder: transport material and as well as for rub them for surface cleaning.

7. Dewater machine: for mechanical surface drying of the material flakes with rotating roller (two series: one for PET, one for PP/PE)

8. Pipe dry system: Using stainless steel "U" type pipeline and cyclone silo to dry the material to the necessary residual level for downstream material processing.

9.Silo: Storage for final products.

General information(Take capacity 500kg/h Waste Film Recycling Production Line as example):

| Raw material | plastic film,bottle,bag etc(PE PP HDPE LDPE PET PVB etc.) |

| Final product & Output capacity | Film flakes / 500kg/h |

| Machine color | Specified by customer |

Work condition (provide by customer):

| Warehouse/Workshop | Supply of cranes, fork-lifts or other lifting equipment; Mounting materials and tools; Workshop dimension (M*M*M):60(L)×5(W)×5(H); |

| Power supply | 380V,50HZ,3PH(or customer's) |

Energy consumption:

| Installation power | 282.6KW (Actual power consumption percentage: 70%) |

| Water supply | Consumption: 10ton/h(Proposed water-treatment project) |

| Ancillary staff | 4-6 Persons |

Main commercial terms:

| Project | 500kg/h Waste Film Recycling Production Line |

| Payment term | 30% as down payment by T/T; 70% by T/T before delivery and after inspection; |

| Container qty. | 1 -2 sets 40HP |

| Delivery time | 60 working days since the date of receiving down payment |

| Packing | Wooden case for important parts,belt ,electric cabinet etc.and plastic film |

| Warranty period | 12months since date of bill of lading |

| Heating type (hot washer) | Steam heating and electric heating(60kw*2sets) |