Plastic Disposable Cup Forming and Stacking Machine

Zhejiang Hongyin Machinery Co., Ltd.- Certification:CE, ISO

- Column number:Four Column

- Molding Method:Pressing

- Automatic Grade:Automatic

- Brand Name:Hongyin

- Model Number:Hy-660

Base Info

- Model NO.:HY-660

- Processing Type:Plastic Thermoforming Machine

- Product Type:Plastic Packaging

- Max Forming Depth:130mm

- Max Forming Area:650*320mm

- Place of Origin:Zhejiang China (Mainland)

- Voltage:380V 50,60Hz

- Dimension(L*W*H):3.7*1.5*2.5 M

- Warranty:1 Year

- Transport Package:Wooden

- Specification:CE

- Trademark:HongYin

- Origin:Zhejiang China

- HS Code:8477409000

- Production Capacity:10 Sets,Month

Description

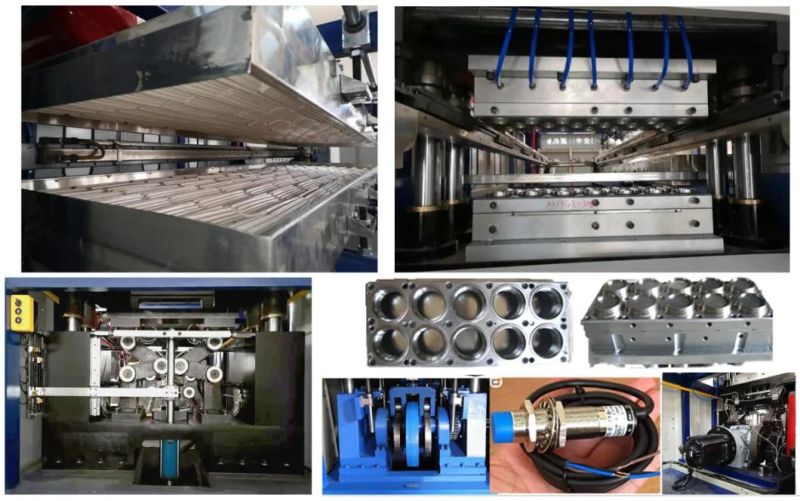

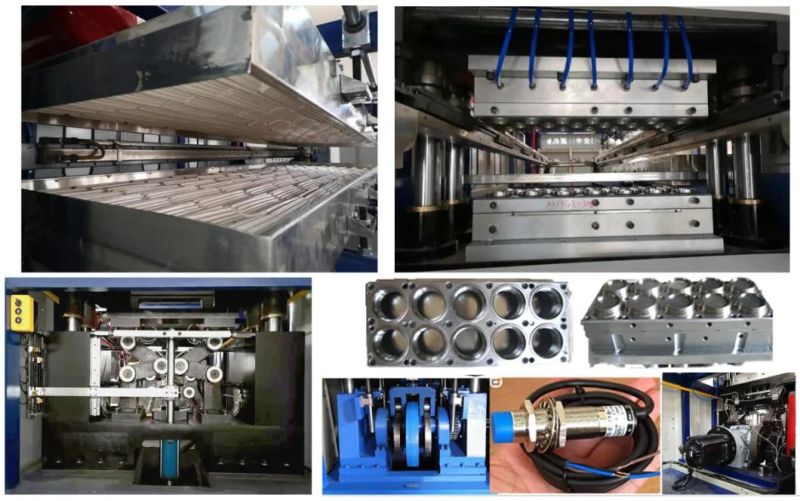

1 Power Supply380V/3P/50HZ 2 Material PP/PS/PET/PVC plastic thermoforming sheet 3 Driving Method Cam+ Air cylinder 4 Forming Area 660×320mm 5 Sheet Thickness 0.25~2.0mm 6 Forming Speed 20-35cycles/min (forming depth≤130mm) 7 Sheet Width W=660mm (adjustable) 8 Air Pressure 0.6~0.8Mpa 9 Air Consumption 2200L/min 10Air Compressor Exhausting Capacity 2200~3000L/min 11Water Consumption 0.5m3 10 Machine Dimension 3.7×1.5×2.5m 11 Electrical Consumption Approx. 45KW A. Forming Machine 1. Machine Frame Square Steel Size 75×75:120 model Channel Steel:machine base is welding by extra steel plate with thickness=16mm 2. Machine Door The top part of the door with observation window from the operation side, Heating oven could move outside 3. Mold Plate QT500 nodular cast iron, pore-free, sand free 4. Pillar 2-pillar dia. = 80mm ,40Cr steel thermal refining ,hard chrome plating,mirror finish:Gide bushing Dia.≤200mm,Material: matel ceramic Zns. 5. Worm Wheel Standard Model 210, made in Taiwan 6. Motor P-5.5KW (4P) 7. Sheet Thickness 0.3~2.0mm 8. Max. Forming Aare 660×320mm 9. Running Speed ≤35cycles/min 10. Stretching Air Cylinder Φ125×125mm 11. Solenoid Valve SMC, Japan B. Sheet Feeding Device 1 Pin-Chain Railway 45# Steel Forgings after nitridation process with hardness: HV740. 2 Pin-Chain Railway Cooling Method Top part and side part cooling by water C. Sheet Feeding Structure 1.Sheet Feeding Precise Within ±0.5cm 2. Within ±0.5cm 2.2KW with Inverter D. Top & Bottom Heating Oven 1 Oven Structure Top & Bottom 2 Material of Oven 304# stainless steel board 3 Temperature Control Method PID K-Type,output adopts voltage adjustor, temperature Precise: ±1ºC Made in China 4 Cradle For Oven Made by 120 model and 100 model channel steel 5 Oven Movement Cylinder Made in China 6.IR Ceramic Heater IR Ceramic Heater, Size:240×80mm:Top oven: machine direction 7pcs*8zones:Bottom oven: machine direction 8pcs*8zones:total: 120pcs, Power: 650W/pcs, made in Jiangsu, China E. Unwinding Rack & Waste Sheet Winder Waste Sheet Winder Motor Power: 0.37KW Worm Wheel Made in China 1.Screw type air compressor 18.5kw/h 3 m3/min 2.Air tank 1.0 m3 3.Chiller 3-5HP 4.Plastic cup stacker 20000-40000(PCS/H) 5.Packaging&counting machine Can choose packing 1-2 row