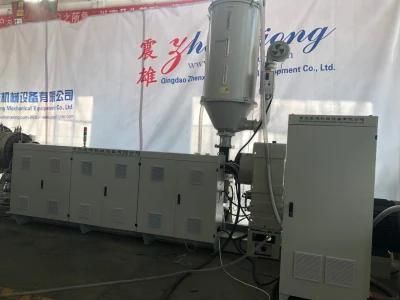

SMS PP Meltblown Machine for Surgical Mask

Qingdao Zhenxiong Mechanical Equipment Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:ZXBN

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Material:PP Chip

- Weight Range:10-100G,M2

- Transport Package:Standard Package

- Specification:CAPACITY

- Trademark:ZX

- Origin:China

- HS Code:84778000

- Production Capacity:10 Sets , Year

Description

Basic Info.

Model NO. ZXBN Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Material PP Chip Weight Range 10-100G/M2 Transport Package Standard Package Specification CAPACITY Trademark ZX Origin China HS Code 84778000 Production Capacity 10 Sets / YearProduct Description

SMS PP Meltblown Machine for Surgical MaskProduct Application

1.Material:PP chip2.Weight range:10-100g/m2

3.Fabric usage:Medical applicant,shopping bag,packing,operation suit,face mask,baby diaper.etc

A.General information for pp spunbond nonwoven machinery

| Model | HHM-1.6SS | HHM-2.4SS | HHM-3.2SS | HHM-4.0SS | HHM-4.8SS |

| Effective Width | 1.6M | 2.4M | 3.2M | 4.0M | 4.8M |

| Weight Range | 10-150G/M2 | 10-150G/M2 | 10-150G/M2 | 10-150G/M2 | 10-150G/M2 |

| Output per Day | 6-10Ton | 10-15Ton | 12-20Ton | 15-25Ton | 18-30Ton |

| Machine Speed | <=350m/min | <=350m/min | <=350m/min | <=350m/min | <=350m/min |

| Transformer Capacity | ≈400KVA | ≈500KVA | ≈800KVA | ≈1000KVA | ≈1250KVA |

| Power Consumption | 700˚-900˚/Ton | 700˚-900˚/Ton | 700˚-900˚/Ton | 700˚-900˚/Ton | 700˚-900˚/Ton |

| Machine Size(L*W*H) | 35M*12M*12M | 35M*15M*12M | 35M*17M*12M | 35M*19M*12M | 35M*21M*12M |

Recycle extruder---->Main extruder---->Filter---->Metering pump---->

Monomer suction device--->Spinning box(Changzhou/ENKA/KASEN spinneret)---->

Quenching air chamber---->Stretching device---->Web former---->

Calender---->Winder---->Slitter

C.Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)---->Raw material----> Melting---->

Filtering---->Measuring ---->Spinning---->Cooling---->Stretching---->

Web forming---->Calendering---->Winding----> Cutting---->Final product

Application: