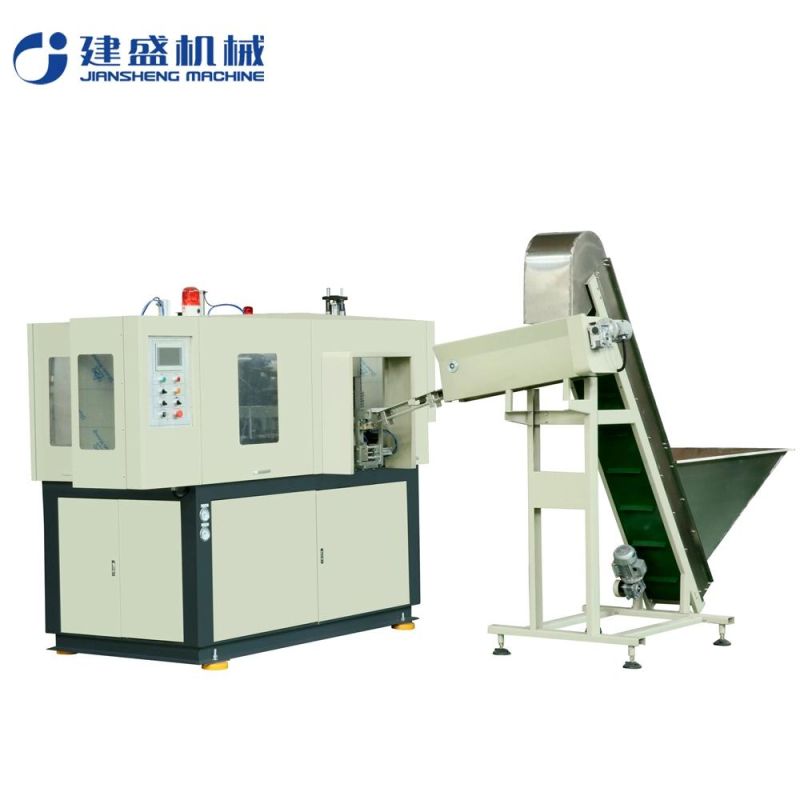

Plastic Machine Pet Beverage Bottle Blowing Mold Machine with CE

Taizhou Jiansheng Machine Co., Ltd.- Type:Stretch Blow Molding Machine

- Bottle Liter:10

- Machine Cavity:1

- Machine Output:600-900PCS,H

- Raw Material:Pet

- Making Method of Parison:Stretch Blow

Base Info

- Model NO.:JS600C

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

- Transport Package:Wooden Box

- Specification:SGS, CE

- Trademark:JS

- Origin:Huangyan Taizhou Zhejiang

- HS Code:84773090

- Production Capacity:600-900PCS,H

Description

Bottle blowing moding machine of JS-600C is one specialty blows makes PET entire to model the bottletwo steps automatically to blow the bottle equipment, most greatly mayblow makes 10L, is suitable to blows the system carbonic acid beveragebottle, the mineral spring thermos, the agricultural medicine bottle, the cosmetics bottle, the small wide mouth bottle and so on, thismachine serviceability broad, the price can be reliable, stabilitygood, the security is good

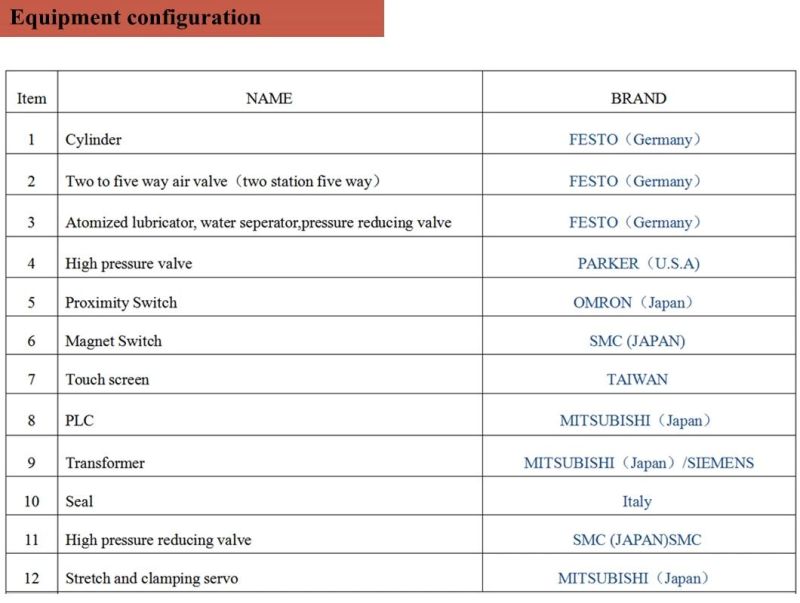

Bottle blowing moding machine of JS-600C is one specialty blows makes PET entire to model the bottletwo steps automatically to blow the bottle equipment, most greatly mayblow makes 10L, is suitable to blows the system carbonic acid beveragebottle, the mineral spring thermos, the agricultural medicine bottle, the cosmetics bottle, the small wide mouth bottle and so on, thismachine serviceability broad, the price can be reliable, stabilitygood, the security is goodA. Uses Mitsubishi (Japan) the computer control system, theperformance is stable;

B. The conveyer automatically deliver the semifinished product;

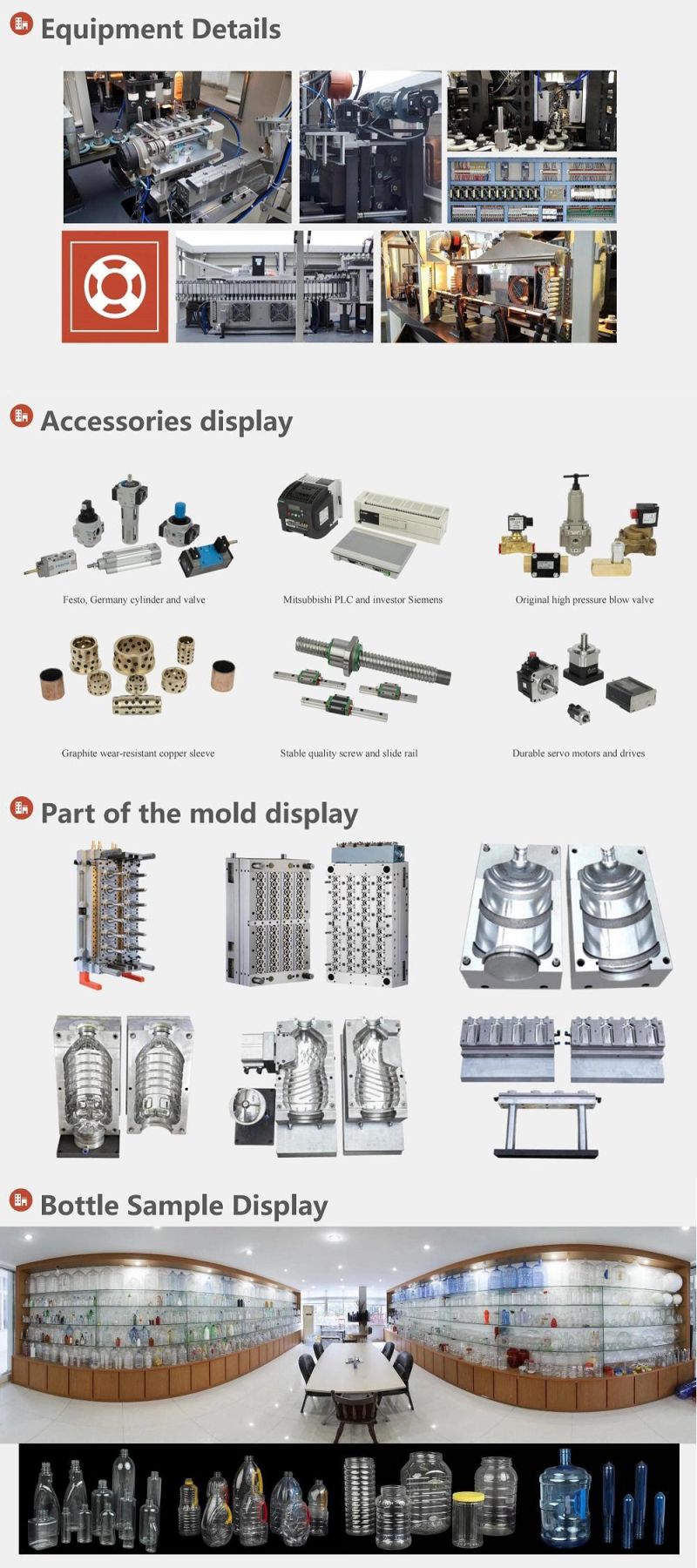

C. Uses the infrared lamp tube to heat up, penetrating power strong, bottle semifinished product rotation being heated, being heated even, the lamp tube, the baffle plate highly may adjust, suits the differentbottle semifinished product, and has the automatic platoon warminstallment, guaranteed dries a constant temperature, is stable istouching the screen adjustment, controls warm fine, holds controls thesimple convenience

D. Each machinery treat as all has the foolproof device, when someworking procedure appears the breakdown, touches the screen auto-alarmdemonstration, putting in order machine cut to secure state;

E. Various movements actuate by the import name brand air cylinder, stable reliable, the service life grows, does not have the pollution, the noise is low and so on the merit;

F. Uses the double crank connecting rod to lock the mold, locks themold strength to be strong;

G. The air course design act and the air flush divides into two parts, satisfiedly will blow the bottle, treats as the different barometricpressure;

H. The operating procedure manually has, the entire automatic twoways; Simple, convenient, is easy to understand;

I. The safe reliable unique valve position design, is lets the aircourse change clear;

J. The production technical process completely automation completes, has the investment province, the efficiency high, the ease ofoperation, the service is simple and so on the merit;

K. The bottle body exempts is polluted;

L. The cooling system achieves centrifugal the cooling effect; Technical Reference

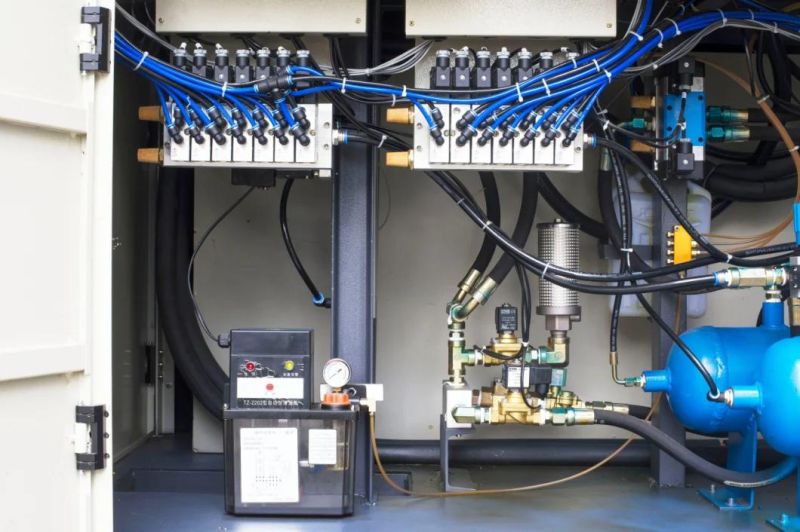

Internal details of the Machine