Plastic Polymer Compounding Parallel Co-Rotating Twin Screw Extruder Price

Nanjing Kairong Machinery Tech. Co., Ltd.- After-sales Service:Engineers Available to Service Machinery Overseas

- Warranty:1 Year

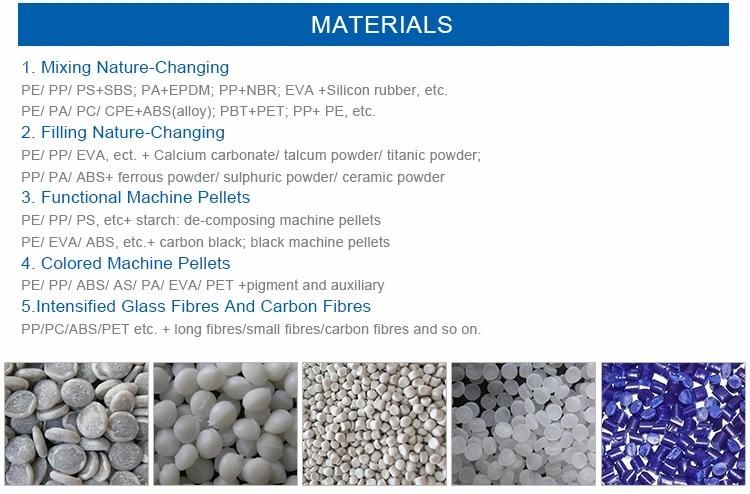

- Raw Material:LDPE HDPE PE PP Pet PA6 PC ABS PVC

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

Base Info

- Model NO.:TSE-65

- Automation:Automatic

- Computerized:Computerized

- Customized:Customized

- Certification:CE, ISO9001:2008

- Condition:New

- Keyword:Twin Screw Extruder

- Place of Origin:Jiangsu, China

- Application:Compounding, Cutting, Pelletizing, Granulating

- Extruder:Parallel Twin Screw Extruder

- Diameter of Screw:62.4mm

- Motor:Wannan or Siemems

- Power:90 Kw

- Screen Changer:Hydrulic Screw Changer

- Comtroller:PLC

- Transport Package:Export Wood Packing with Soft Plastic Foam

- Specification:CE ISO9001

- Trademark:kaironggroup

- Origin:Nanjing Jiangsu

- HS Code:84772090

- Production Capacity:300sets,Year

Description

1.Electric control system

Frame structure control cabinet

Imported electrical elements

Imported temperature control system

Imported driving system

Interlock and multi-protection

Adopting imported PLC (OMRON or SIMES ) to achieve optimized process control.Stronger function, steady performance and much higher accuracy.

It can be also accomplished full-set link-lock protection, trouble safeguard, fault alarm cluing and so on

Operation interface on touching screen is visual and marked, which is brief and easy to use.

2.The Gearbox

New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and the torque assignment get together, which keeo it compact, and the key bearings are imported.

The select material of drive components is dainty.Including super intension alloy cementiteing steel, cementiting and quenching, gear grinding technics, strengthening of tooth face.So they can ensure high torque, high precision and low noise.

Soakage and coerce lubrication integrate smoothly.When the hydraulic circuit is over pressed, it alarms

4.The Screw Barrel

Euro-style rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller

According to the material and special techinics demands, the material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding process

The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat- treament

FAQ

1. Q:Are you factory or trading company?

A: We are manufacturer.

2. Q: What makes you different from other suppliers?

A: 1) firstly,our factory is very professional in twin screw extruder for many years, and our machine's

quality is best in our field and our price is also competitive from other suppliers.

2) second,our service is very excellent.and our engerneers is avaliable to service the machine overseas

and if you have any questions you can contact us at any time,we will reply you in 24hours.

3. Q:What is the payment?

A: 1) T/T payment; 30% T/T in advance ,balance before shippment. 2) L/C or contact us for other ways.